6. The S-11 flies out

When the series production of the S-11 started, it was also known what the sales of the aircraft looked like.

The delivery of the S-11s would look like this: 39 for the LSK/KLu that would use them for basic flight training, 41 for the Israeli Air Force, 2 for the National Aviation School, 11 for components delivered to Macchi in Italy as a precursor to the license construction that was to start there, 5 units in components to Brazil also as the start-up phase of a licensing program, the prototypes remained with Fokker.

Sales of the S-11, for example, were very different from the initial order of Frits Diepen Aircraft NV

The delivery to the LSK/KLu, Israeli Air Force and RLS took place between 1949 and 1952.

All S-11s built in Amsterdam North were transported by deck barge to the Fokker flight shed at Schiphol-East, later to the new Fokker factory at Schiphol-East that was put into use in 1951.

From there they were made ready to fly, flown in and delivered.

In 1952 the S-11 production stopped at the Fokker factory in Amsterdam North.

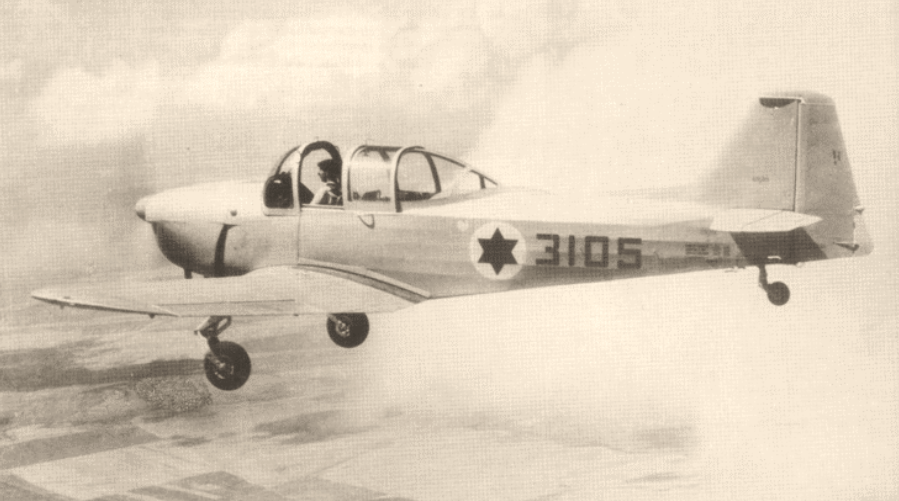

Israel

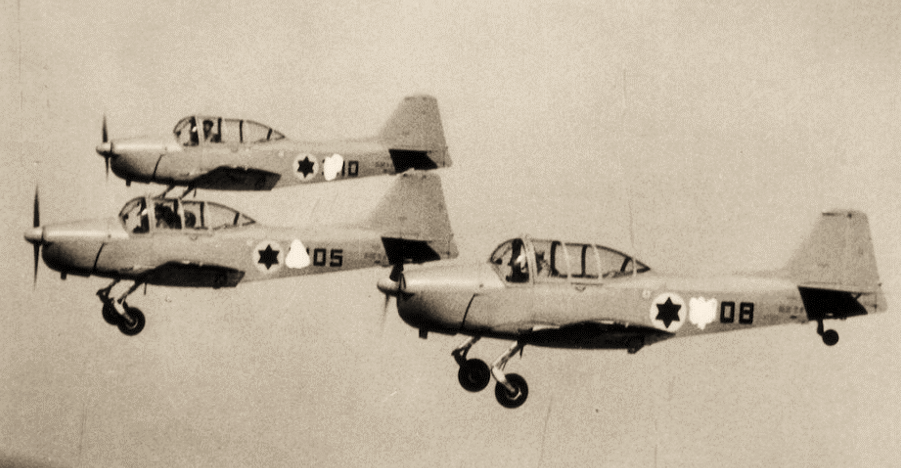

Shipments of Israeli S-11s started in the early months of 1951.

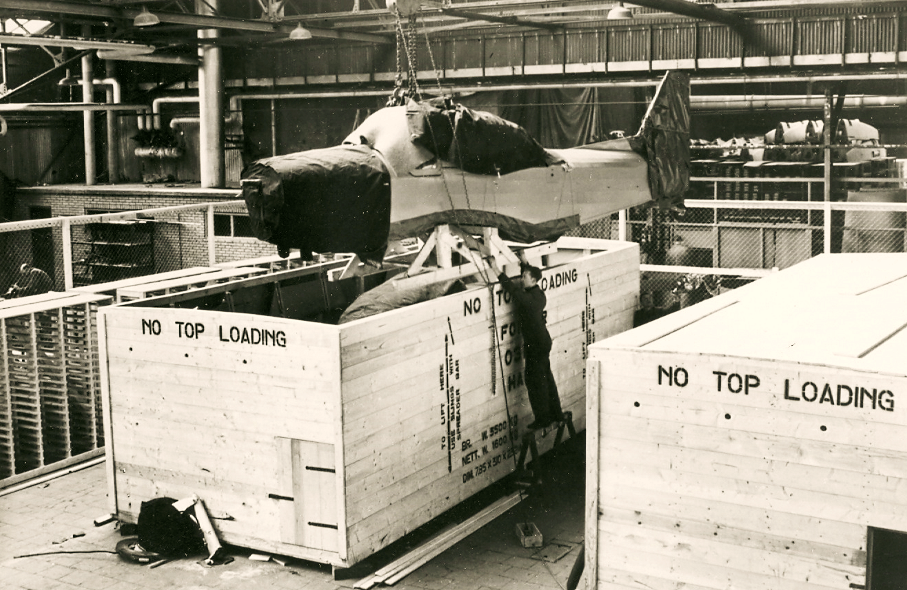

The S-11s were all shipped in components per crate to the Israeli port of Haifa and were assembled into a complete aircraft on site at the newly established Bedek Aircraft factory.

The S-11s that were built for Israel were designated S-11.2 and had some differences compared to the LSK/KLu planes.

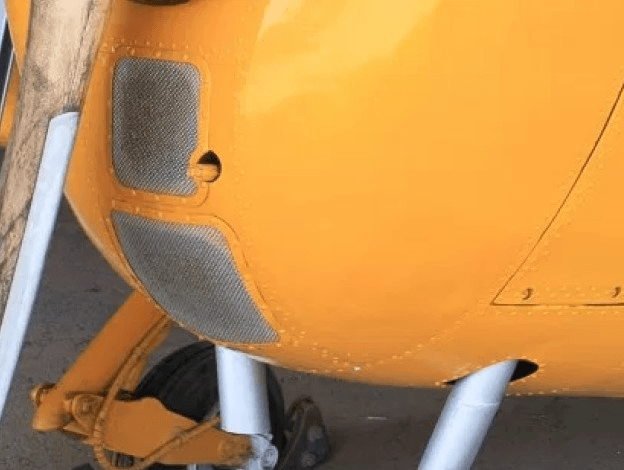

The cockpit hood had larger vents, different shapes of controls, protective grilles over the air intakes and an enlarged trim tab in the rudder that was also operable from the cockpit.

The enlarged trim tab made the S-11.2 6 cm. longer than the Dutch version

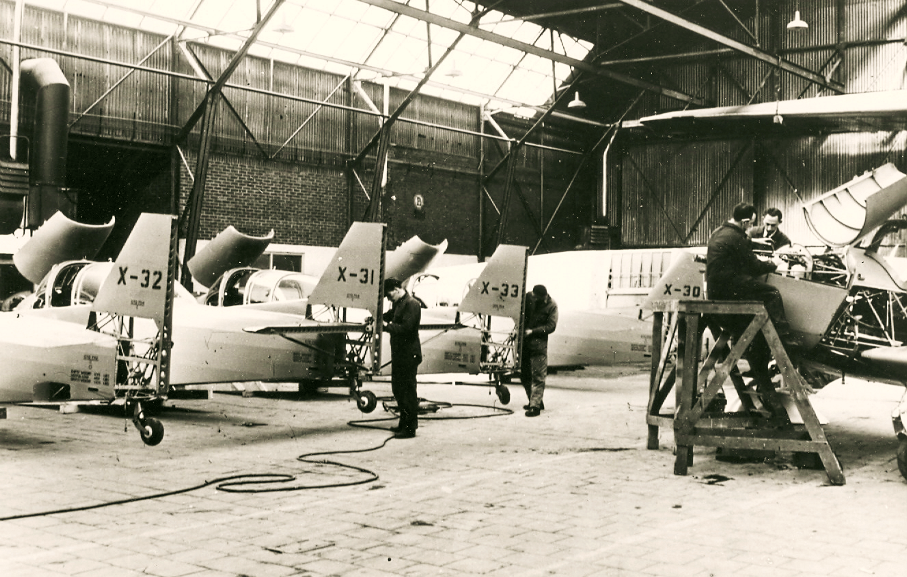

The S-11s for Israel have all been registered in the Netherlands,

X-18 to X-57, these registrations were already applied to the aircraft during production.

Registrations 3101 to 3140 were kept at the Israeli Air Force.

Later it would be somewhat confirmed that the S-11 would not have been used so intensively, by the Israeli Air Force.

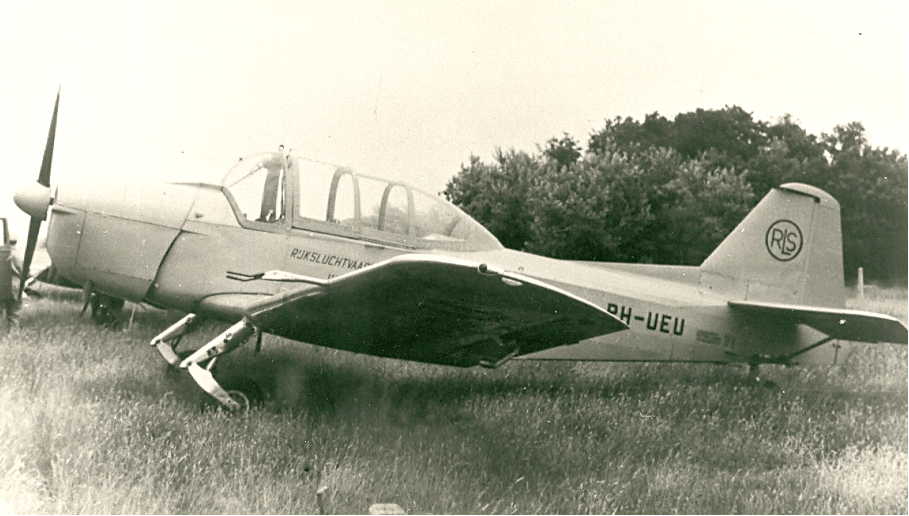

On June 9, 1950 the S-11 was registered as PH-UEU in the name of the RLD, Rijks Luchtvaart Dienst and was used under this registration with the RLS.

On 17 July 1950 the plane was returned to Fokker with registration PH-NED.

With this registration, this S-11 had four more owners and was burned on August 19, 1968 at Seppe airport.

The second RLS S-11 had cn 6194 and was actually intended for the Royal Netherlands Air Force with registration E-5, but was registered on June 1, 1950 as PH-NED in the name of Fokker.

On July 17, 1950, the plane was again registered PH-UEU in the name of the RLD and thus used by the RLS.

On this date, this chest was the replacement for the previous one.

Unfortunately, the plane crashed on June 15, 1956 near Hilversum airport.

Naturally, the Royal Netherlands Air Forces received an S-11 with a different cn as E-5.

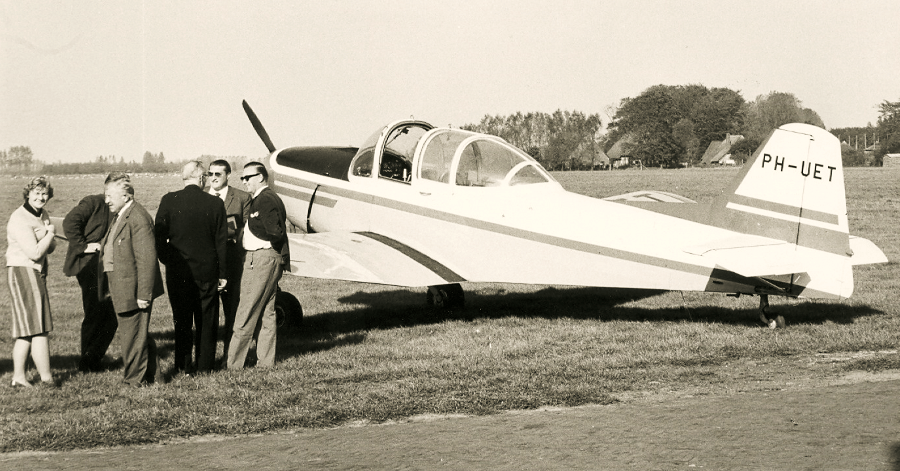

The third RLS S-11 had cn 6198 and was registered on June 9, 1950 as PH-UET in the name of the RLD and thus delivered directly to the RLS.

On August 1, 1960 the aircraft was deregistered as PH-UET and was no longer used by the RLS.

After having had three private owners, this S-11 ended up in the collection of the Aviodome at Schiphol in the 1970s via TU Delft.

From 1946, the National Aviation School first operated at the Gilze Rijen military base, later that year partly at Ypenburg airport near The Hague and finally in 1954 from Eelde airport.

So there were three S-11s registered in the Dutch Aviation Register in the name of the RLD/RLS, but they only operated with two at a time.

Color Schemes

The RLS S-11s were painted bright yellow, including the spinner, the RLS text on the fuselage and the RLS logos on the tail were black.

The small registrations on the fuselage were black, as were the registrations on the right and under the left wing.

on the deck of the French ship "Tomoe" in the port of Rotterdam, to leave for America at midnight.

The voyage went well and on October 7, 1952, the Tomoe entered New York Harbor.

Early the next morning, both aircraft were unloaded and transported over the water to New York Airport, La Guardia.

Once there, the planes were made ready to fly to the Fairchild factory at Hagerstown, about 120 km northwest of Washington.

On October 10, 1952, both planes departed from La Guardia, arriving at the Fairchild factory after a flight of just under two hours.

Soon after their arrival, the boxes were handed over to Fairchild in good order.

The next day the boxes were properly dismantled by Fairchild technicians,

They were very surprised about the simplicity and good accessibility of the aircraft.

Both planes remained with the Fairchild factories for quite some time, because only in the second half of 1953 did both planes return to Dutch soil.

Unfortunately, the long stay had been in vain, for by the end of 1953 it was announced that both the S-11 and the S-12 were of no interest in the United States.

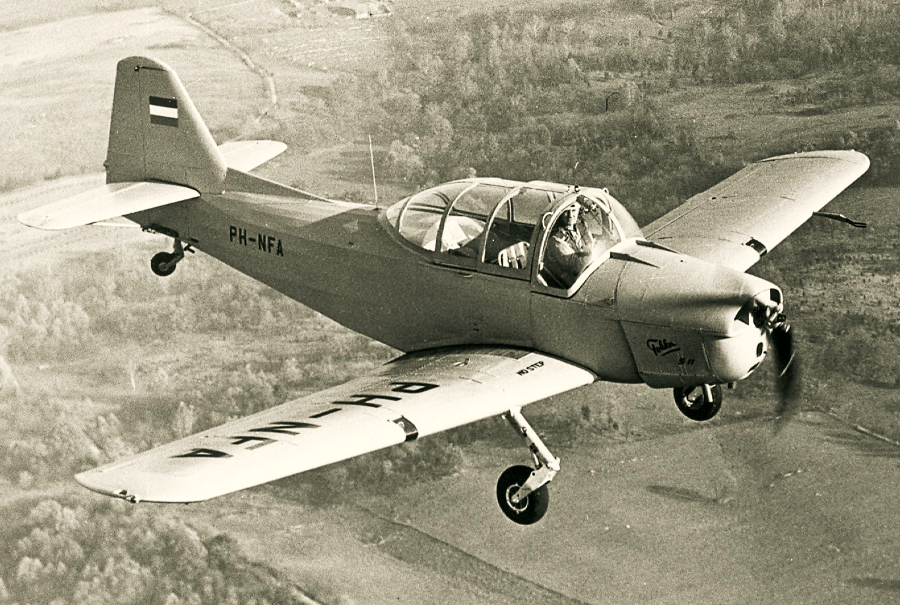

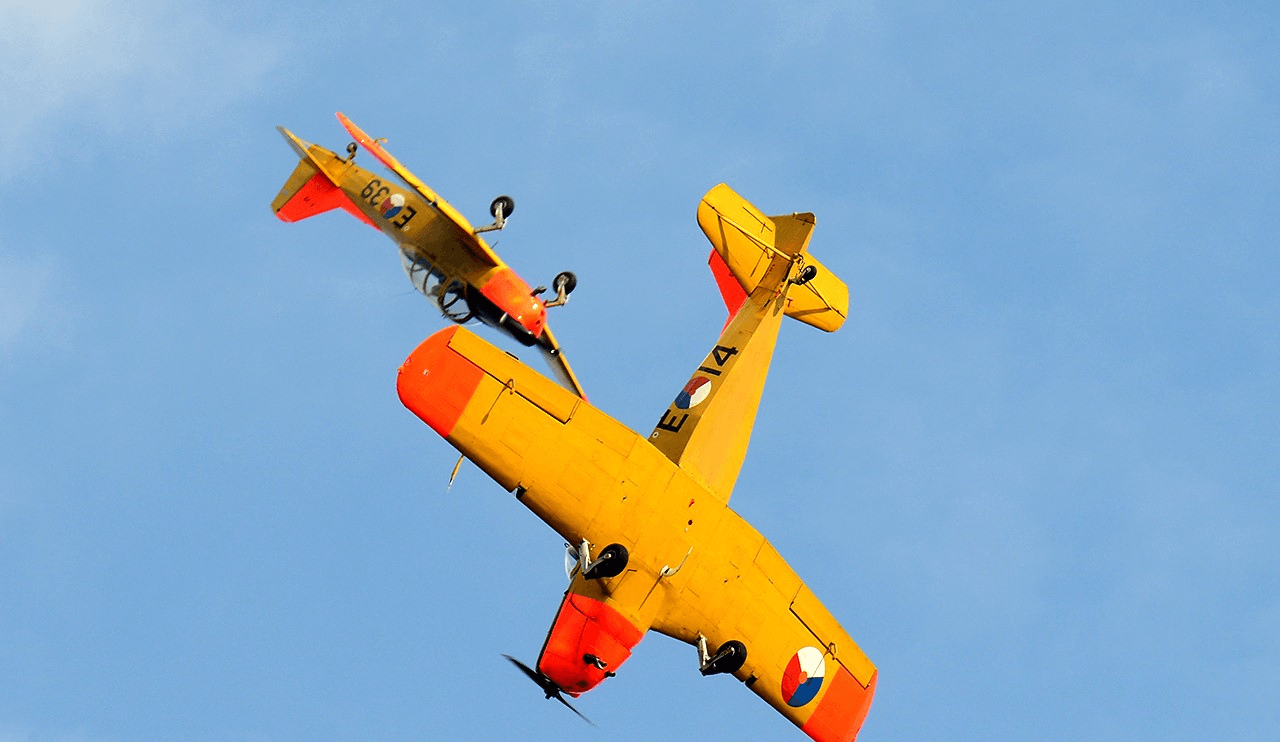

The S-11 that has been on American soil had cn 6275 and registration PH-NFA and was later delivered to the Air Force as the last S-11 as E-39 and at this moment (2018) still airworthy.

The aircraft was extremely suitable for this, because of the good view from the cockpit.

On February 3, an S-11 made a landing on a dry piece of ground in the emergency area and took off from there.

On July 18, 1953, the Air Force celebrated its anniversary with a large flying party

40th anniversary.

Besides the Air Force's own S-11s, Fokker also made a contribution by flying an S-11 in front.

With Fokker test pilot Gerben Sonderman at the controls, it was not just a matter of flying ahead, but he showed what the S-11 is capable of by showing a considerable number of Aerobatic or aerobatics.

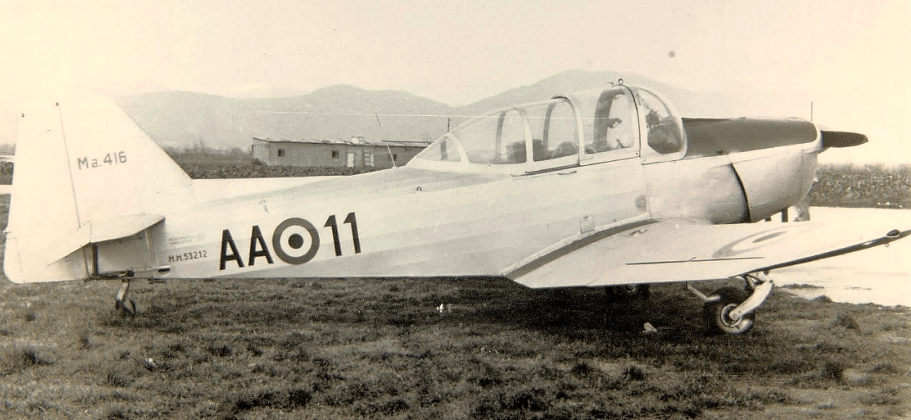

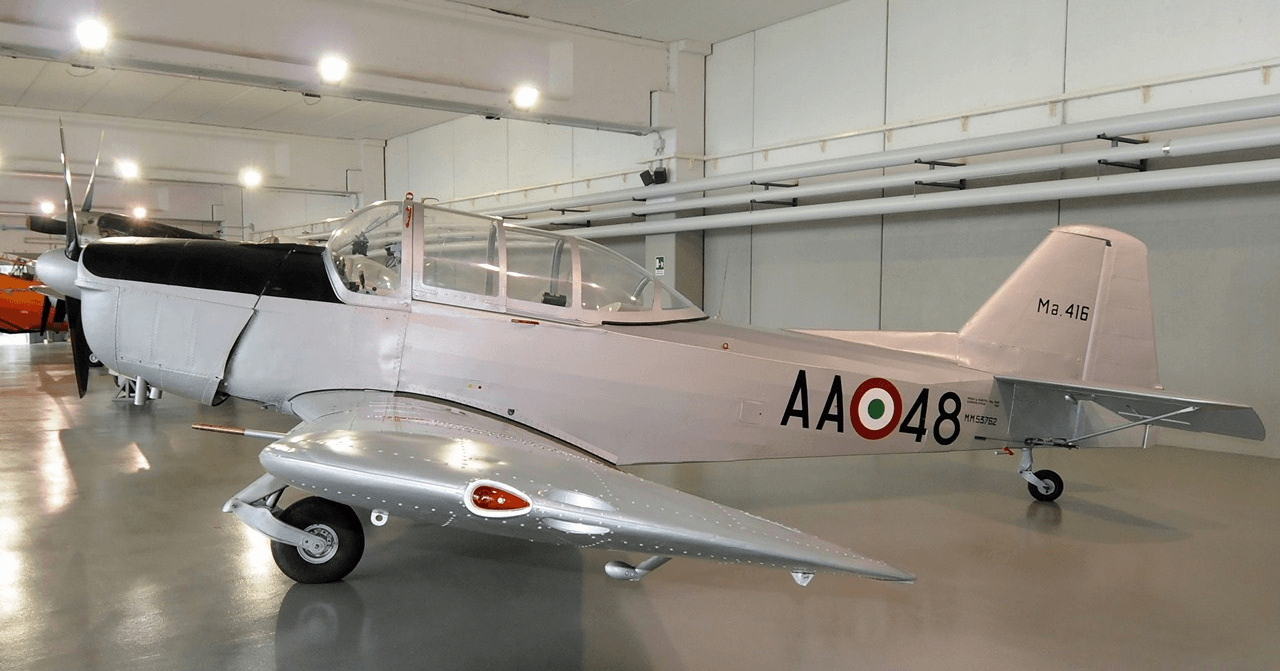

The Italians were in quite a hurry to put the M-416 into service, which is why the IMAM factory in Naples was sub-licensed to produce 60 M-416s. So a total of 180 S-11s/M416s were built in Italy.

In the Netherlands the Italian S-11s were designated S-11.3.

The S-11.3/M-416, like the Israeli version, had a larger trim tab in the rudder that was adjustable from the cockpit.

The cockpit was also arranged differently, the left instrument panel was green and the right panel was arranged differently.

The handles on the left of the cockpit and on the column were different in shape.

In preparation for production, Fokker delivered 11 aircraft in components to Macchi, 10 complete and 1 fuselage, which were sent to Italy by rail.

Between 1960 and 1965, the M-416s were gradually withdrawn from service.

After being used by the air force, many M-416s were put into use as civilian aircraft in Italy and ended up in aviation museums.

Color Schemes

The Macchi M-416s were all painted aluminum, the anti-glare on the hood was matte black and some spinners too.

The Italian Air Force roundels were mounted on and under both wings and on both sides of the fuselage.

The registrations were on the hull left and right of the roundels with the MM codes next to it.

Left and right on the vertical fin was the type designation Ma. 416 applied.

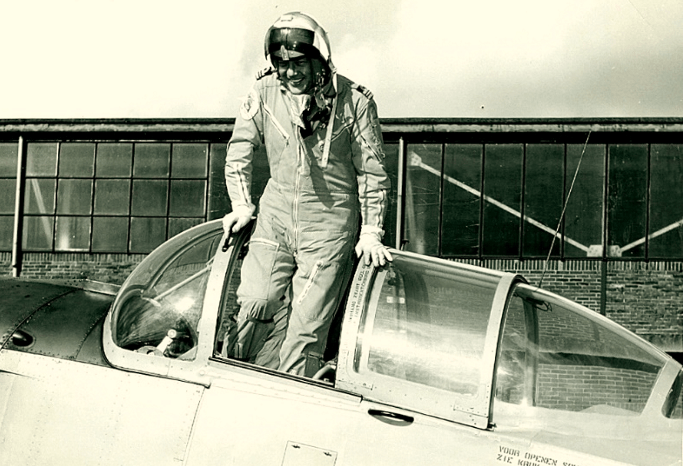

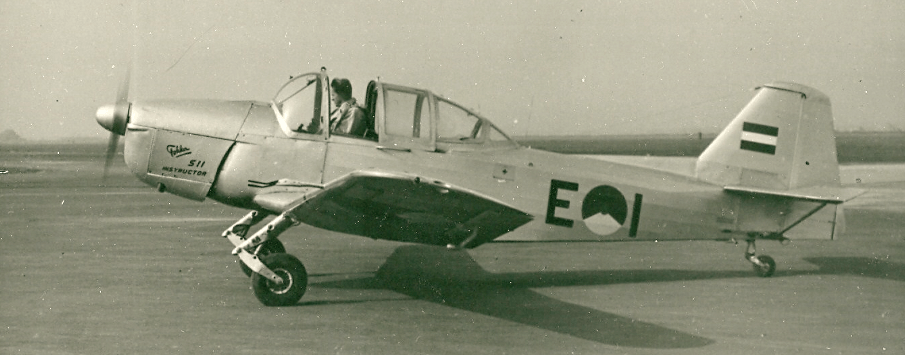

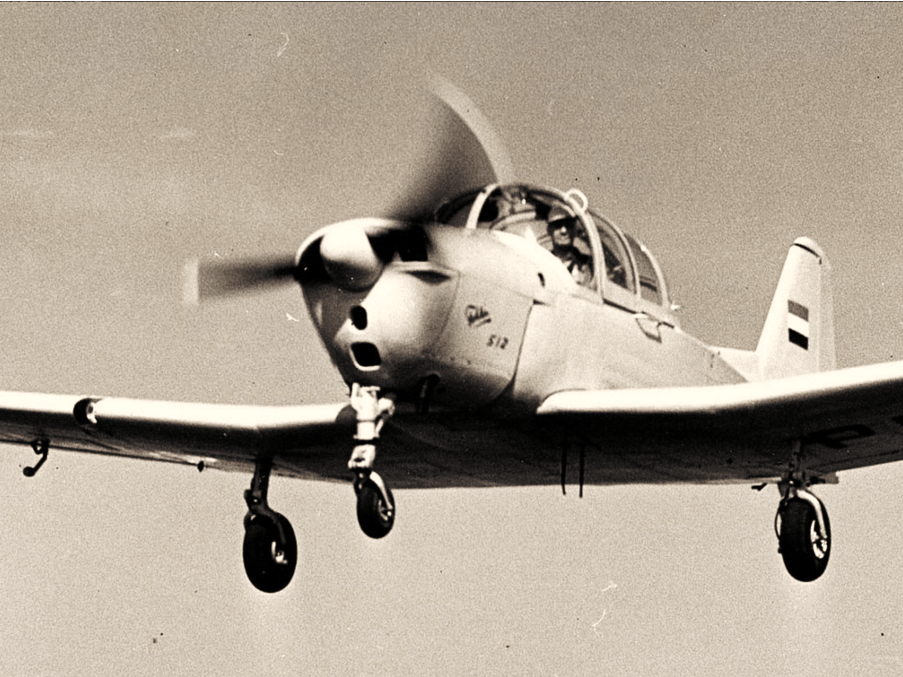

7. The S-11 at the LSK/ Dutch Royal Air Force

39 S-11s have been used by the Royal Netherlands Air Force. 40 were supposed to have been ordered, but in the end 39 were delivered.

All S-11s were still delivered to the LSK, on March 27, 1953 it became part

“Royal Air Force”, the S-11s had registrations E-1 through E-39 and operated from 1950 to 1973.

The S-11 was first stationed at Woensdrecht Air Base at the EVO, Elementary Flight Training, but was later moved to Gilze Rijen Air Base.

Student pilots were trained on the S-11 for approximately 30 hours, after flying between 12 and 16 hours under the guidance of a flight instructor, the student pilots were able to fly solo on the S-11.

Take-off and landing with the S-11 had to be done with the cockpit hood open for safety reasons.

The chance of a rollover with the S-11 was always present, after all, it was flown by student pilots, the presence of the tailwheel also gave the possibility of a nose position, especially with the (wrong) take-off procedure, followed by possibly a rollover.

With an open cockpit hood, the pilots could then more easily leave the aircraft in such a situation.

Wearing a crash helmet/flying helmet for both pilots in the S-11 was also mandatory in the Air Force.

Hundreds of pilots have had their training on the S-11, after which they transfer to other Air Force aircraft and after their employment with the Air Force, they end up on civilian aircraft at KLM, Martinair, etc.

In 1958, when the S-11 was operational for almost eight years with the Air Force, Fokker requested the Air Force to prepare a report on the experience with the S-11 in terms of flight characteristics and technical aspects.

In that report, the Air Force pointed out, among other things, the following shortcomings of the S-11:

The flight characteristics

Prolonged climbs are very tiring for the pilot because a constant deflection to the right of the rudder is required.

The trim tab in the rudder cannot be operated from the cockpit, but can be operated on the Israeli and Italian S-11s.

The directional stability is very poor and during rain the view through the plexiglass cockpit hood is very poor.

When landing, the rudder must always be turned to the left, again due to the lack of trim tab adjustment from the cockpit.

The seat belts in the seats are difficult to handle and after a long flight the instructors complain of back pain due to the position of the seats, tilted too much forward.

In the general comments, the Air Force literally writes the following in the report:

“In practice, the flight characteristics of the Fokker S-11 appear to be sufficient,

at least for the basic training for which the plane is now in use.

The valves, which were initially reported less favorably, also appear to be sufficiently effective.”

Technical aspects

The main landing gear showed cracks after 2 to 3 years, which meant that reinforcements had to be installed.

At the moment Italian landing gears from the company Nardi are being tested.

Due to the wooden propeller, the climbing capacities were moderate and the KLu mounted self-regulating Aeromatic propellers.

There is no heating in the cockpit, the Royal Dutch Air Forces installed it themselves.

The night lighting on the instrument panel is not satisfactory at all.

The inspection and maintenance options are generally reasonable, the battery and the radio installed by the Royal Netherlands Air Forces are difficult to reach.

In 1957 the average flight readiness of the S-11 was 70% at the Royal Netherlands Air Forces,

in 1958, the flight readiness dropped to 50%, partly due to difficulties with the Aeromatic propellers.

According to the report drawn up by the Royal Netherlands Air Forces at the request of Fokker.

In general, the S-11 has always had a lot of glitches in the later placed VHF or UHF radios.

Also, despite its 190 horsepower, the engine was found to be regularly underpowered in some maneuvers while flying, especially at high outside temperatures.

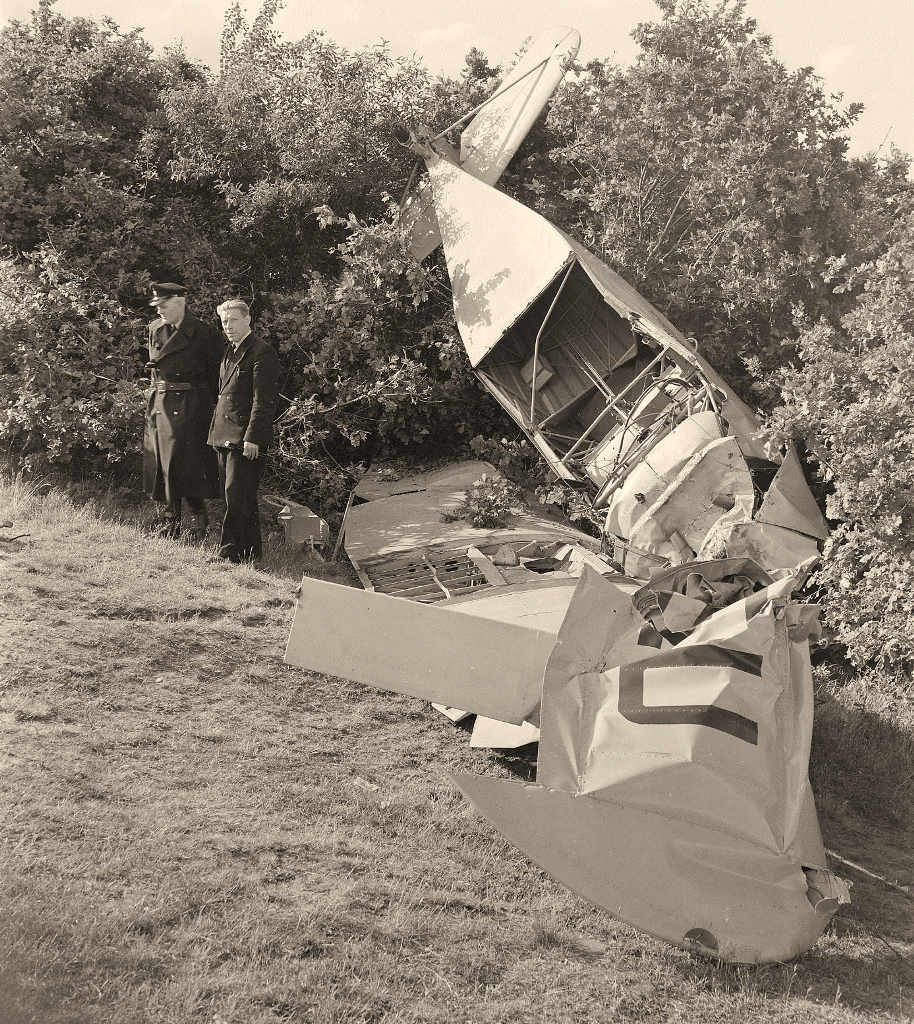

Accidents

There have been 45 accidents with the S-11 in the Air Force, 32 minor accidents, 11 serious and 2 irreparable.

Most accidents were caused by colliding with obstacles while taxiing, on a number of S-11s the left or right wheel leg broke during taxiing or on landing.

After an accident with the E-23 on July 29, 1953, the remains of this S-11 were used for instruction material at the LETS, Air Force Electronic and Technical School, at the Air Force Base in Deelen.

The fuselage of the E-5, which crashed on March 1, 1972, went to the LETS for the Air Force firefighting training.

Some S-11s could be repaired by the Air Force or at Fokker, a number of irreparable S-11s were scrapped.

On September 3, 1973, the last 14 S-11s at Gilze Rijen were taken out of service.

After this, dozens have come into private hands in and outside the Netherlands

for making fun flights.

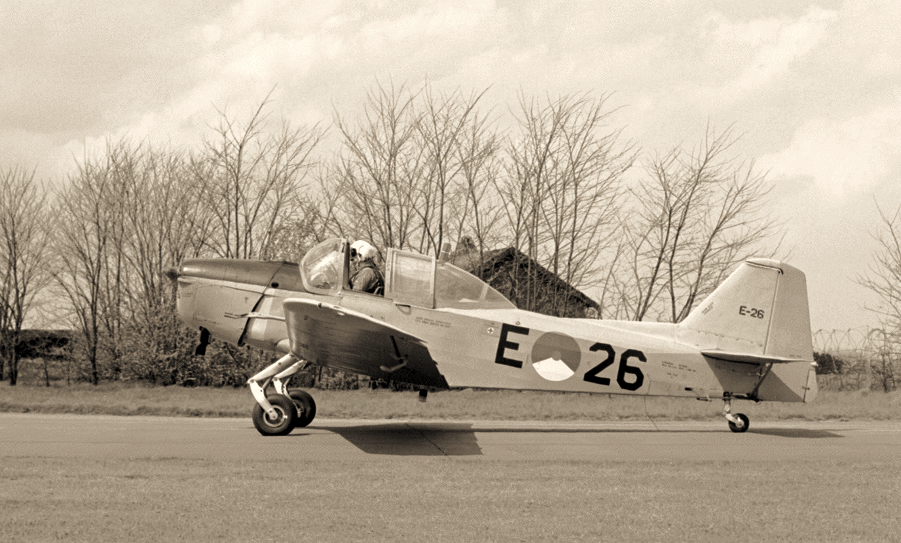

Color schemes

The LSK/KLu S-11s have had 4 different color schemes during their periods there, some with a major change, some with a smaller one.

When delivered in 1950, the wings were made of white polished aluminum, the fuselage and spinners were painted bright yellow.

Roundels were placed on the left and right sides of the wings, both on the top and the bottom.

The registration was applied to the left and right of the fuselage to the left and right of the roundels, the Dutch flag was applied to the left and right of the vertical tail.

Shortly after delivery, the wings were also painted bright yellow, but everything else remained the same.

The boxes were fitted in 1957 with a small pointy piece of matte black anti-glare on the hood, over the full width of the windshield, to a point, towards the propeller hub.

In 1959 a major change in the color scheme was made.

Reflective dayglow was applied to the wing tips, vertical tail including dorsal fin and engine siding on the sides and underside.

The roundels only on the right upper and left lower wing.

The flag on the vertical tail disappeared and the registration took its place, the anti-glare was now applied over the entire hood.

Later with this color scheme the roundels with the registrations on the hull were still

2 cm. placed upwards .

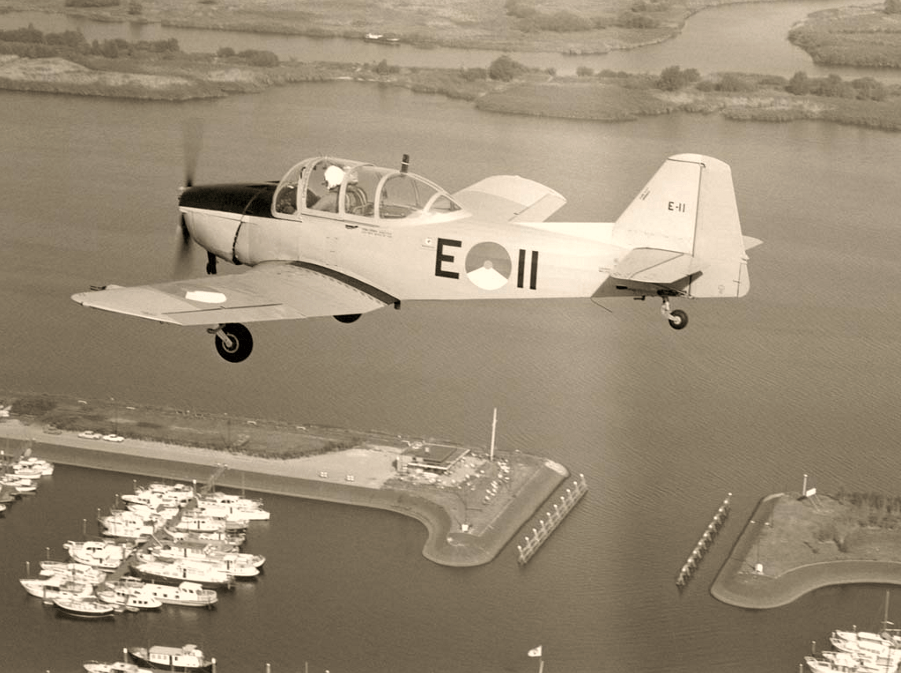

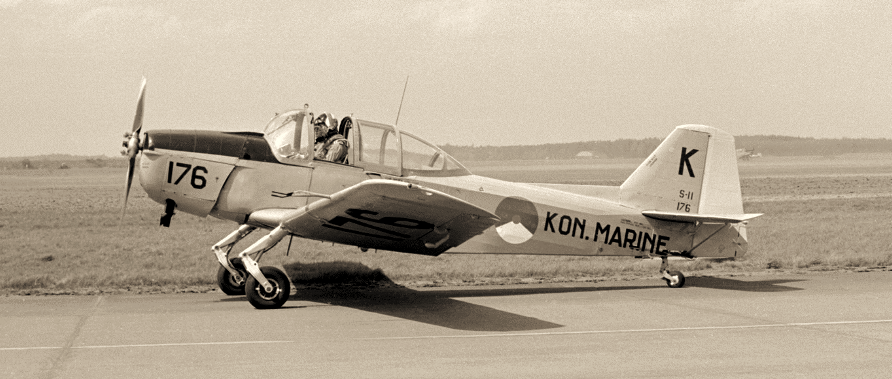

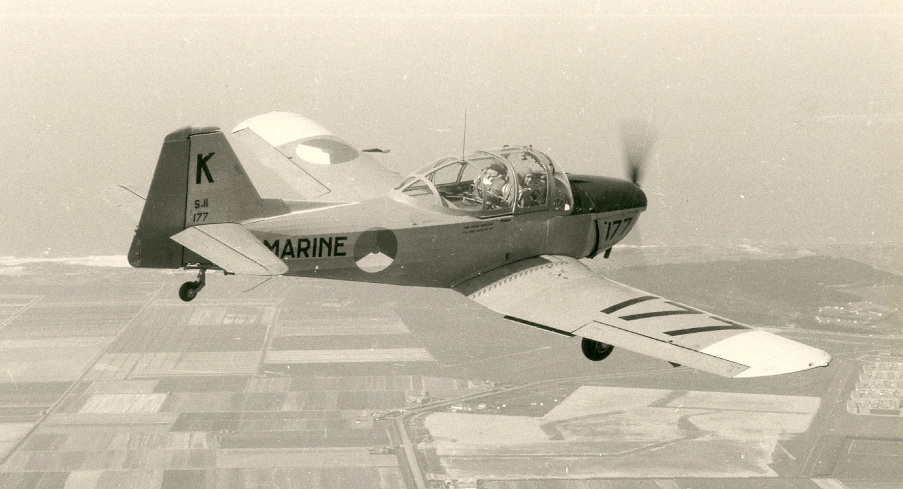

The S-11 at the MLD, Naval Aviation Service

The MLD used the S-11 for years at the Kooy airfield in den Helder for the training of Midshipmen.

This happened with 22 aircraft that were alternately borrowed/used from the Air Force in the period between 1959 and 1969.

Later, in 1970, 9 S-11s were taken over from the Air Force and received the MLD registrations 174 to 179 and 197 to 199.

The S-11s were assigned to the VSQ-9 squadron on the Kooy and were fitted on the tailboard of a large K of the Kooy, on August 28, 1973 the MLD S-11s were withdrawn from service.

Color Schemes

The color scheme on the MLD S-11s was changed when they were taken over from the Royal Netherlands Air Force.

The dayglow remained, the MLD registration was moved downwards on the vertical fin with the type designation “S-11” above it, a large black K, van de Kooy, was applied at the top of the vertical fin.

The MLD registration was applied in large size to the left and right of the engine cowling, plus the top right and bottom left of the wing.

Between the roundels on the fuselage and the tailwheel, the text KON. NAVY applied..

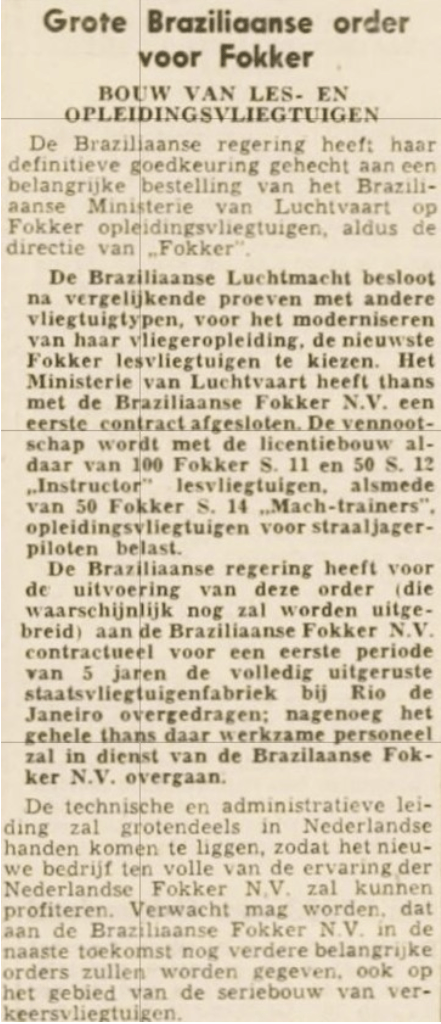

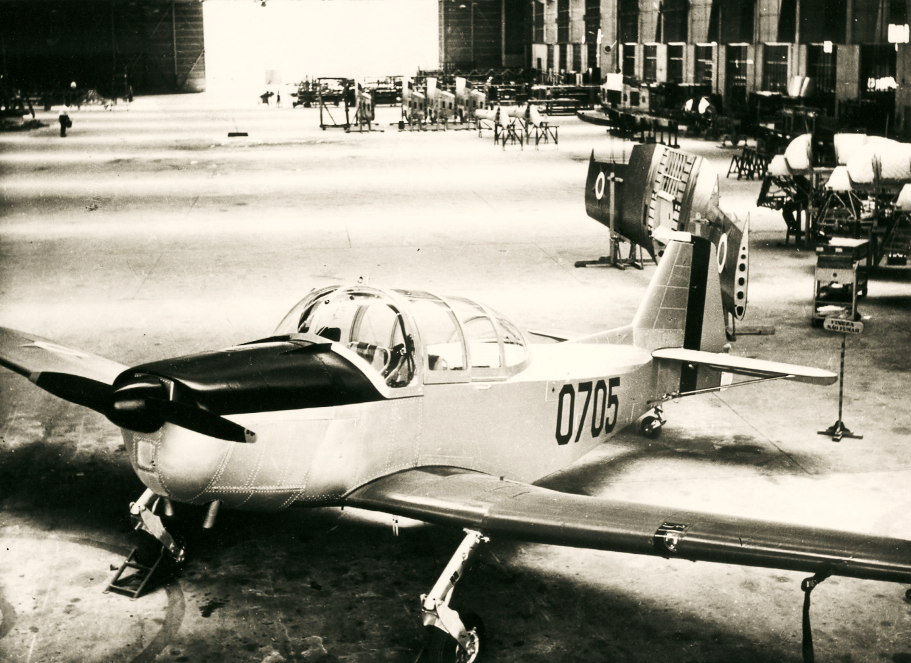

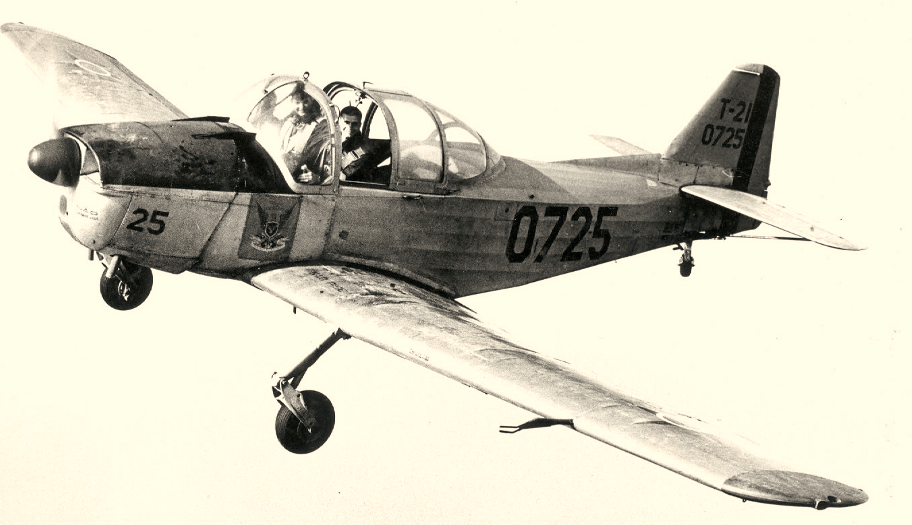

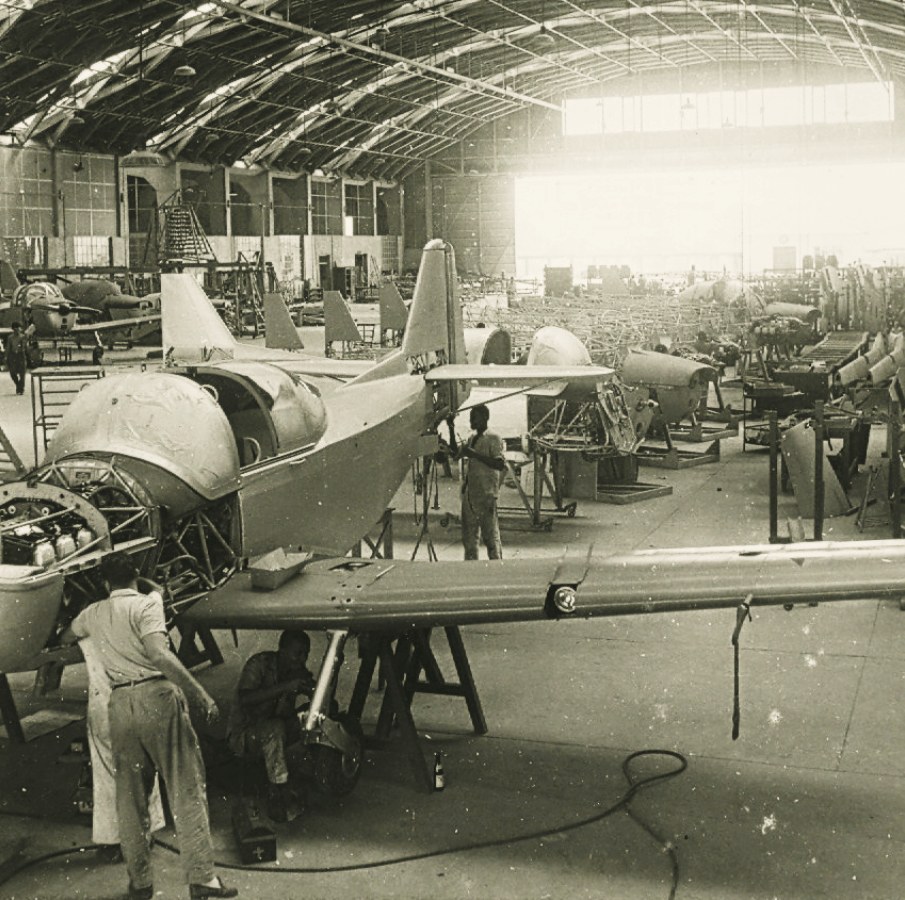

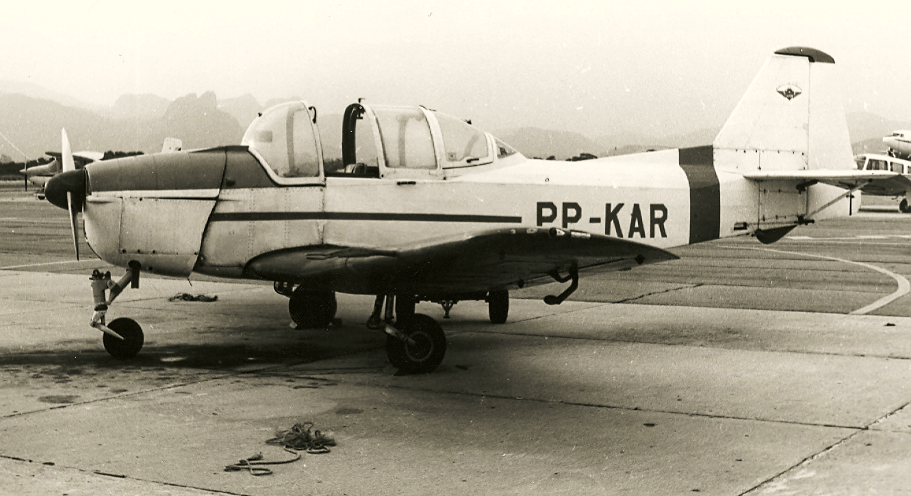

8. Fokker Rio

The Brazilian license-building program of the S-11 and S-12 was cast in a different form from that in Italy at Macchi.

The factory where production would take place would be 50% owned by Fokker.

On May 11, 1953, the “Fokker Industria Aeronautica SA” was founded in Rio de Janeiro and shares were even issued.

The company was contracted by the Brazilian government to produce 100 units of S-11 and 50 units of S-12.

Both types were intended for the Brazilian Air Force, which was going to use them for pilot training.

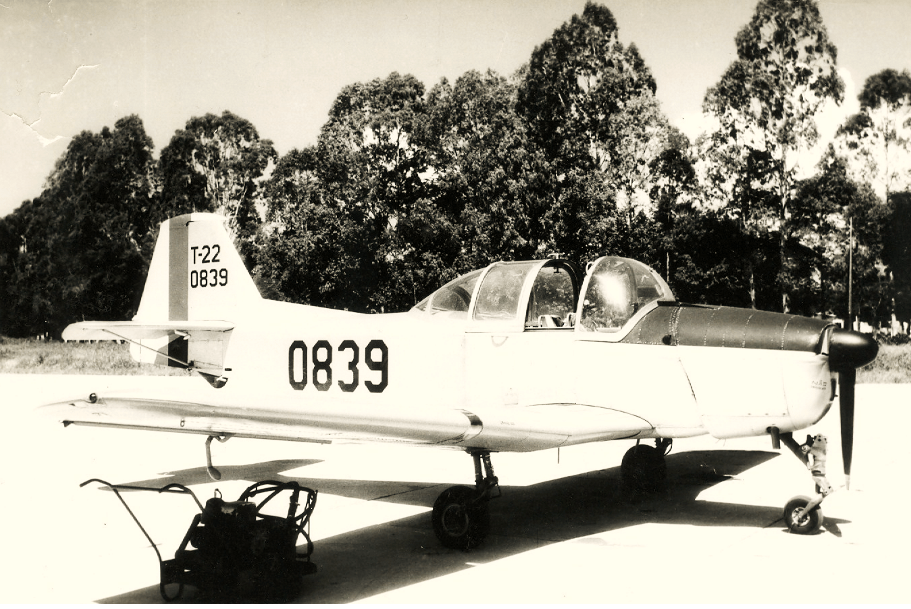

In the Brazilian Air Force, the S-11 was designated as T-21 and the S-12 as

T-22, in the Netherlands the Brazilian S-11 was designated S-11.4.

Fokker supplied the license data, drawings, construction calibers, plus five complete aircraft in components for the start-up phase.

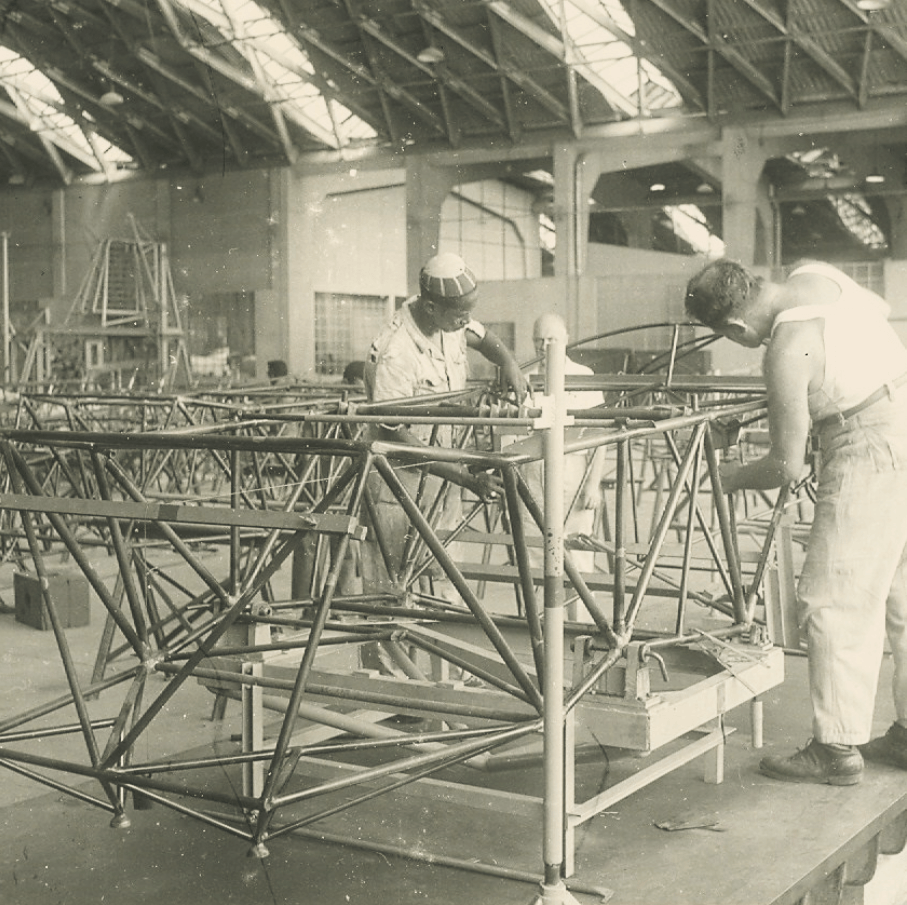

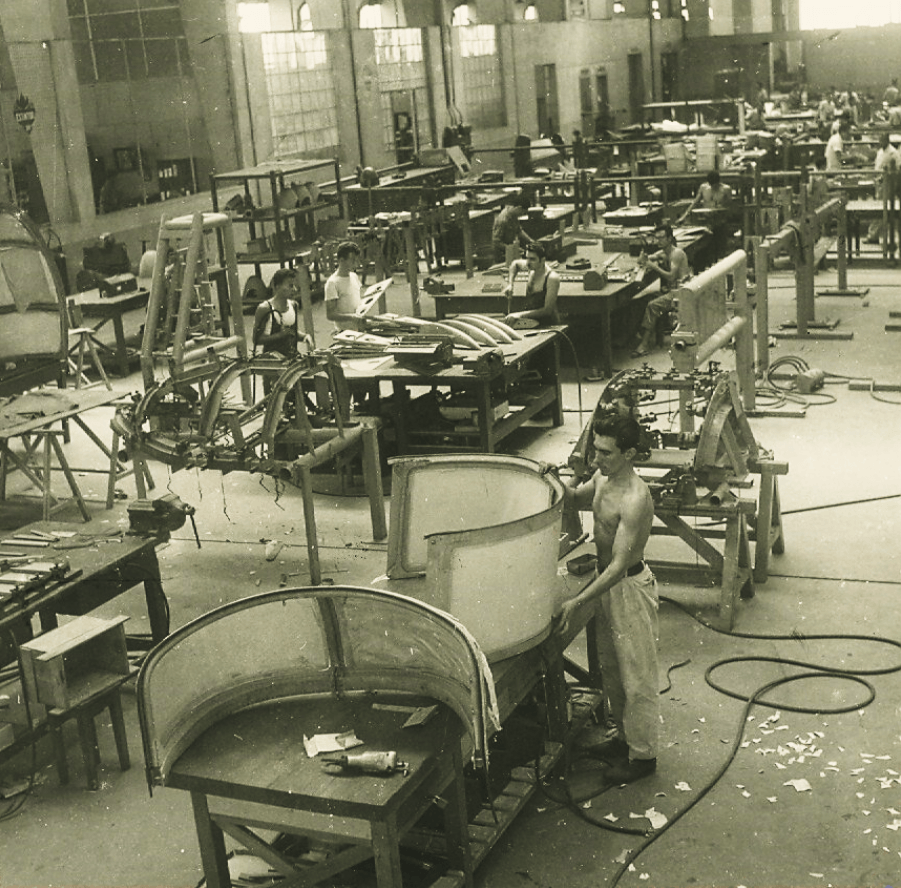

It was no easy task to set up a total production line in Rio for the construction of the T-21 and T-22.

That is why various employees from different departments soon left Amsterdam for support to Fokker Rio, as the company was soon called.

On November 3, 1953, the Heren Helderman, tool construction bureau and Balder, material control, left for Rio, to be followed on November 12 by Mr. Hellebrekers, who had been included in the management of Fokker Rio.

In early 1954 many Fokker employees arrived, sometimes together with their families, because their stay in Rio would be quite long.

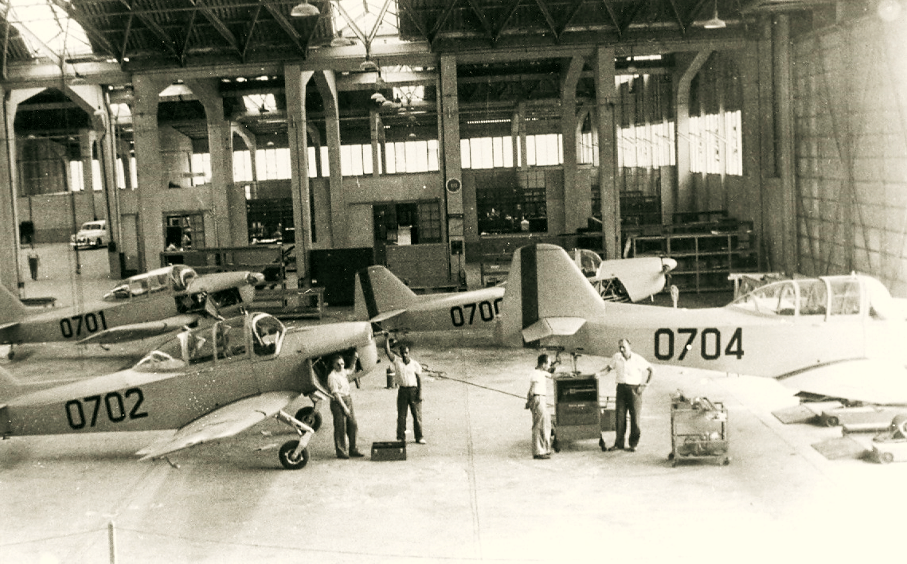

After the start-up phase was over, production could start.

In November 1954, 4 of the 5 component T-21s were solidified and ready for their maiden flight at the end of November.

On November 22, the first Rio assembled T-21 rolled onto the runway for its maiden test flight.

One or more test flights were made with all aircraft at a brisk pace so that they could then be delivered to the Brazilian Air Force.

One T-21 was equipped with additional measuring equipment to measure the performance in the

warm humid Brazilian climate.

Also in Brazil, the use of the T-21 and T-22 showed that the plane was generally underpowered.

The climate in Rio was ideal for flight tests and test flights, not a day was lost due to bad weather conditions that made it impossible to fly.

Major Keller of the Brazilian Air Force, who already knew the S-11 from his visit to Fokker at Schiphol-East, flew as an observer on a number of flights for performance measurements.

Since the flight results were completely in line with expectations, Major Keller was able to fly after 4 T-21s a week later for the technical takeover.

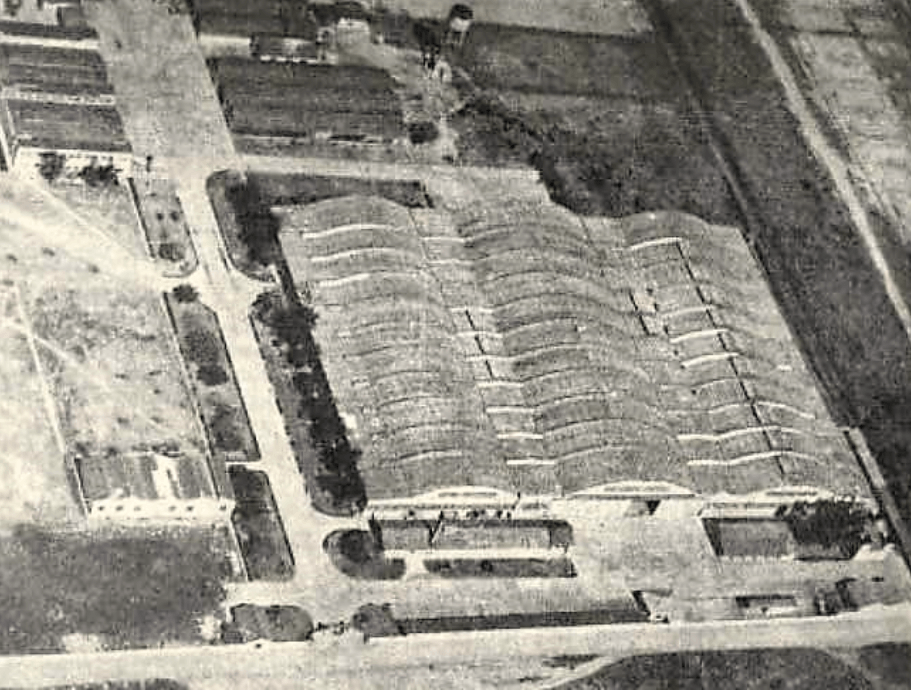

Fokker Rio was housed in a factory that was built by the German aircraft manufacturer in 1937

Focke Wulff in Rio de Janeiro was dropped at Galeao International Airport.

The total factory area was approximately 1/3 of that of the Fokker factory at Schiphol-East at that time and mainly consisted of three large interconnected halls.

During the Second World War, the Brazilians had built a training aircraft of the Fairchild PT-19 type under license.

Before the arrival of Fokker in 1953, 70 Gloster Meteors were assembled.

Furthermore, the factory partly served as a storage place for the Brazilian Air Force.

Ironically, the Embraer aircraft factory is now located in the same place, São José dos Campos.

As a production plane, the factory had virtually come to a standstill in 1953 and a lot of work had to be done to clear up remains from the past if they wanted to start producing aircraft again.

A large part of the existing machinery was repaired in-house and made ready for production again.

A solution to this, which quickly solved the problem, was to set up a kind of business school.

Soon after the start-up of this business school, about 30 people could become part of the production staff in the factory after completing the training.

At the end of 1955 early 1956 the T-21 production was in full swing.

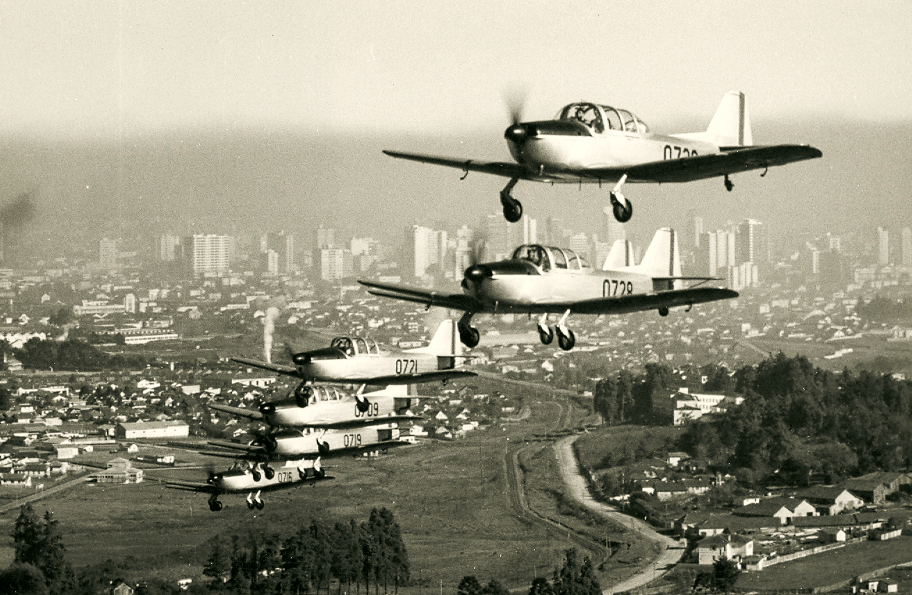

Due to the efforts of everyone involved in the production at Fokker Rio, on 11 February 1957, in the presence of the President of Brazil, the Ministers of Aviation and Navy, the Dutch ambassador and many other invited guests, the first series of 15 Fokker Rio T -21 aircraft, to be transferred to the Brazilian Air Force.

By July 1958 the hull construction department had delivered 75 welded hulls to the final assembly department.

In 1957, the production of the T-21 was delayed by six months because the Brazilian government did not fulfill its financial agreements with Fokker.

Everything also went according to plan in the final assembly department itself, at that time there were,

July 1958, 60 complete aircraft delivered.

In addition, two planes were ready for the final inspection and two were busy with their flight program, while the assembly department was working on about 20 aircraft.

By early August 1958, a total of 66 T-21s had been delivered to the Brazilian Air Force.

Of those 66, 5 have been returned to the Aeronautica factory for a short time,

not because of complaints or imperfections, but to carry out minor repairs.

During the training of the young inexperienced pilots, small obstacles were often overlooked while taxiing to the runway.

As in the Netherlands with the EVO, this caused sheet metal damage to the wings.

In July 1958 the total number of employees at Fokker Rio had risen to 804.

August 1958 was also a bit of a black period in the Fokker Rio history, because 2 T-21's crashed.

Fitting a new wing was often cheaper and faster than a repair, sometimes wings were so damaged that repair was not even possible anymore.

On Saturday, December 20, 1958 at 4 o'clock in the afternoon the Aeronautica factory was hit by a heavy storm, which quickly turned into a cyclone and was accompanied by heavy rain showers.

The trees surrounding the factory were torn from the ground, hundreds of square meters of roofing was destroyed.

The factory's roofing consisted of heavy eternit sheets, which flew through the factory in pieces and pieces, causing a lot of damage to wings, through which the fragments went right through.

Fortunately, there were no injuries at the factory, as it was Saturday there was less staff present.

All in all, the natural disaster has delayed T-21 production by about a month.

Fortunately, before the natural disaster of December 20, there was more pleasant news.

An aviation week was held in Rio de Janeiro, which included the day of the “Aviador”.

During this day, a statement by Brazilian aviation pioneer Alberto Santos Dumont would come true.

He once said "Give Brazil wings and we will fly over it" and lo and behold

48 T-21s flew in two formations over the Aeronautica factory, the largest S-11/T-21 Formation of all time.

During the aviation week, the then Fokker director Mr. van Emden was interviewed by Brazilian television, where he talked about the possibilities of exporting the S-11/T-21 from Brazil to Peru, Bolivia and Venezuela.

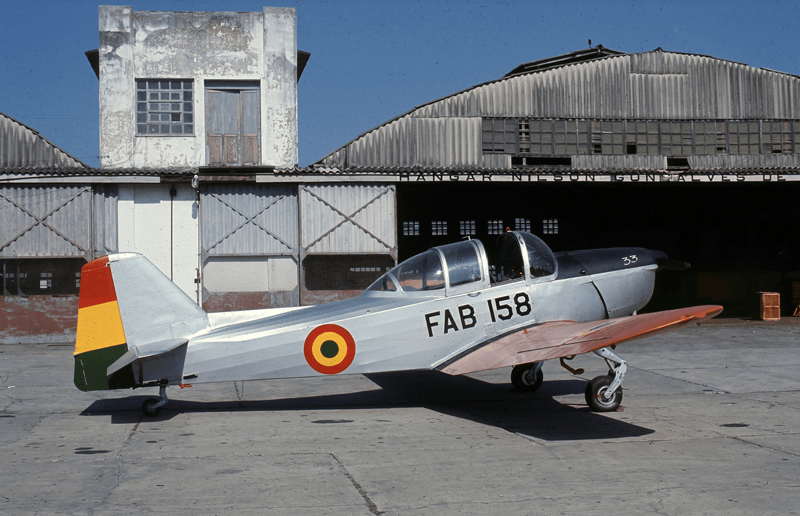

Unfortunately, nothing ever came of these exports, but the Brazilian Air Force later donated eight T-21s to the Bolivian Air Force and eight to the Paraquay Air Force.

The Bolivians were registered FAB-151 to FAB-158, the Paraguayans were registered as 0025 to 0039, but then only the odd numbers, later this changed to FA-025 to FA-039 again only the odd numbers. numbers.

after that, some planes that were already in use by the Brazilian Air Force came back for repair work.

5 of the 12 boxes present for repair were delivered again in March 1959.

After the production of the T-21, production of 50 T-22s was started.

At the end of February 1959, 20 of a total of 50 T-22 hulls were ready at the hull assembly department.

The first T-22 wings were also released from the caliber so that the T-22 production could start.

After some difficulties in the beginning with the final assembly of the T-22, production went smoothly afterwards.

The Brazilian-built T-22s had the access hatch in the back of the cockpit hood to reach the third seat, just like in the S-11 prototypes.

After delivery of the last T-22 and the last repair work, the Dutch Fokker employees left for the chilly homeland.

When she returned home, she had fond memories of the Fokker Rio period.

A number of both the T-21 and the T-22 ended up at flying clubs and museums after their Air Force period.

Both the T-21 and the T-22 had aluminum colored painted hulls with the hood matt black anti-glare, the spinners were also matt black.

The wings and stabilizer were painted in a glossy red/orange, the rudder had a vertical yellow and green stripe.

The registrations were on the hull and the vertical fin, with the type designation T-21 or T-22 on the vertical fin above.

Roundels were fitted on both wings below and above.

The Bolivian T-21 kept the aluminum fuselage and red/orange wings, the registration was left and right in black on the fuselage and the rudder had 3 horizontal stripes, red, yellow, green, from top to bottom.

Roundels were fitted on both wings below and above.

Black anti-glare on the hood and black spinners.

The T-21s for Paraquay also kept the Brazilian aluminum fuselage, the wings and stabilizer were also painted aluminum.

The aluminum colored fuselage had a wide red/orange slash, the wing tips were also red/orange.

The registration was on the fuselage in black, on the vertical tail the type “T-21” was written in black.

Three horizontal stripes were applied to the rudder, red, white, blue, from top to bottom, in the white area was a gold-colored star in the middle.

Black anti-glare on the hood and black spinners.

In the meantime, the S-11 flew at the Royal Netherlands Air Forces, the Italian Air Force, the Brazilian Air Force, where they were also produced and the Israeli S-11s were

no longer in service with the Israeli Air Force.

The S-11s from Israel were therefore the first that became available to be flown by private individuals.

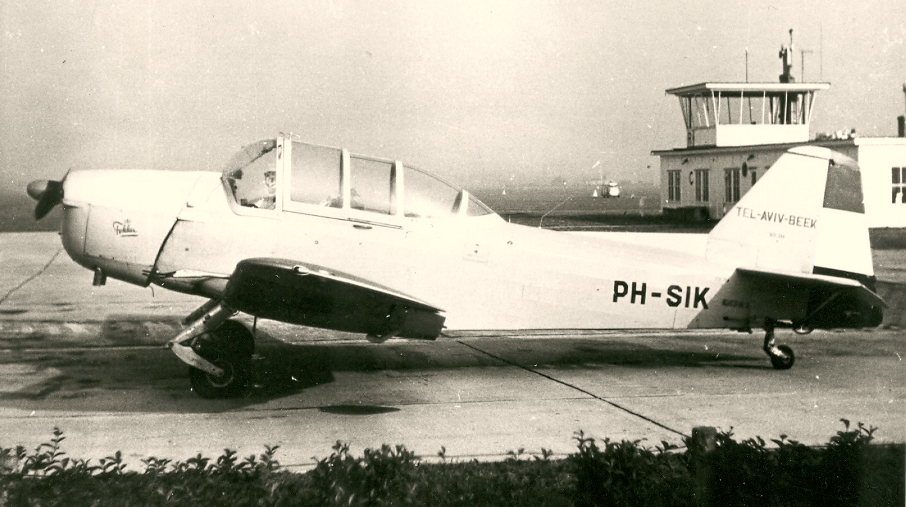

In 1959 the Maastricht sports and advertising pilot Marcel Smeets had bought an S-11 in Israel from the Bedek Aircraft factory in Tel Aviv, which had bought a number of S-11s from the Air Force to resell to private owners.

Mr. Smeets flew the aircraft from Tel Aviv to the then Beek airport, now Maastricht Aachen, in South Limburg, after having first thoroughly performed a number of flights over Israeli territory.

The 4000 Km. long route he flew from Tel Aviv via Cyprus via Rhodes, Athens, Corfu, Brindissi, Rome, Cannes, Lyon, Paris to the airport Beek.

In total, the flight lasted six days, including a rest day, with a total flight time of 30 hours.

After his arrival in the Netherlands with this S-11, Mr. Smeets stated that he got the impression that the S-11s that Fokker had delivered to the Israeli Air Force in 1951, had not received the treatment they needed.

On July 2, 1959, the S-11 of Mr. Smeets, which in the meantime had obtained the registration PH-SIK, was delivered to the Fokker factory at Schiphol-East to undergo a thorough inspection.

On January 22, 1962, Mr. Smeets' S-11 PH-SIK sadly disappeared in the North Sea.

The 23-year-old pilot Ben Kleyn went down with the aircraft, his body was never recovered.

The disappearance of the PH-SIK has quite a few mysteries, the cause of the accident has never been determined, and there was also doubt whether it was not a preconceived plan to collect insurance funds.

The aircraft was sighted north of Calais by the Norwegian tanker Sagona, which was sailing in the North Sea at the time.

The S-11 flew low over the Sagona twice, the second time throwing a dark pack from the S-11 into the sea, later this pack was identified

like an uninflated dinghy.

According to eyewitnesses from Sagona, the S-11 made a normal engine noise when flying low and did not appear to be in distress.

The S-11 hit at a distance of about 250 meters. of the Sagona the sea surface where the wings broke off.

The Sagona immediately sent out a rescue boat which was on the scene within ten minutes, except for the aforementioned dinghy, part of a parachute, a seat cushion and a pair of pilot gloves, nothing was found.

The rest of the day they searched for the kite, but it was never found.

The need for an emergency landing at sea was never apparent, in the time the pilot used for the flights over the Sagona, he could also have flown to the highly visible English coast.

During the investigation into the cause of the accident, there was no legal evidence of insurance fraud, on the basis of which the owner was acquitted on June 1, 1962 for lack of evidence.

Initially, the public prosecutor in Maastricht had the owner of the S-11 arrested a few days after the accident.

The two S-11s were bought by Mr. Pilaar from Zutphen and were delivered by ship in components, after which they were transported to a hangar at Teuge airport.

The intention was to make these S-11s airworthy again, but this never happened, probably parts of these S-11s were sold and the other remains were scrapped.

Mr. Pilaar had already become the proud owner of the ex RLS S-11 in 1961

PH-UET.

The ex X-56 cn 6255 was now registered in Israel as 4X-ADR in the civil aviation register.

Mr. Schmeling was very satisfied with his S-11, with which he not only flew pleasure flights, but also lifted gliders on a cable attached to his S-11.

Mr. Schmeling also came up with the previously mentioned story that the Israeli Air Force S-11s had been bought by the Bedek Aircraft factory and had sold a number of them to Burma, now Myanmar.

In the 1960s, for example, a number of S-11s came into private ownership.

In the Netherlands we had to wait for that until the 1970s until the finished S-11s of the KLu/MLD were offered for sale by the Domains Service.

When that was the case, a number of S-11s did indeed end up with Dutch private pilots or flying clubs.

Five S-11s then ended up in Belgium and were also provided with Belgian civil registrations.

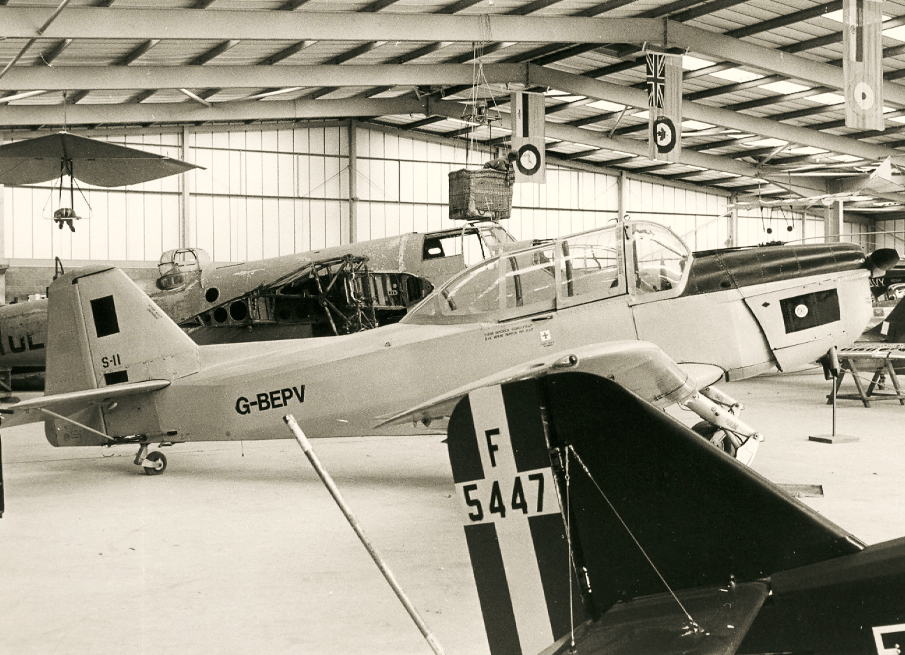

Two S-11s ended up in England, one of which was included in the famous Strathallan Collection in Pertshire, Scotland.

In 2005 the ex KLu E-17, which had flown around Belgium for a few years as OO-MCH, ended up in the United States with the Dutch owner Cor de Blij with registration N17FK.

Cor de Blij was one of the pilots of an S-11 of the Fokker Four in the Netherlands from the start in 1982 and was part of the pilot corps of the Fokker Four for years.

A second S-11 that ended up in the United States in 2004 is the ex-KLu

E-11 and now owned by Clifford Heathcoat in California registered

N911J.

Both S-11s are currently still flying in the United States.

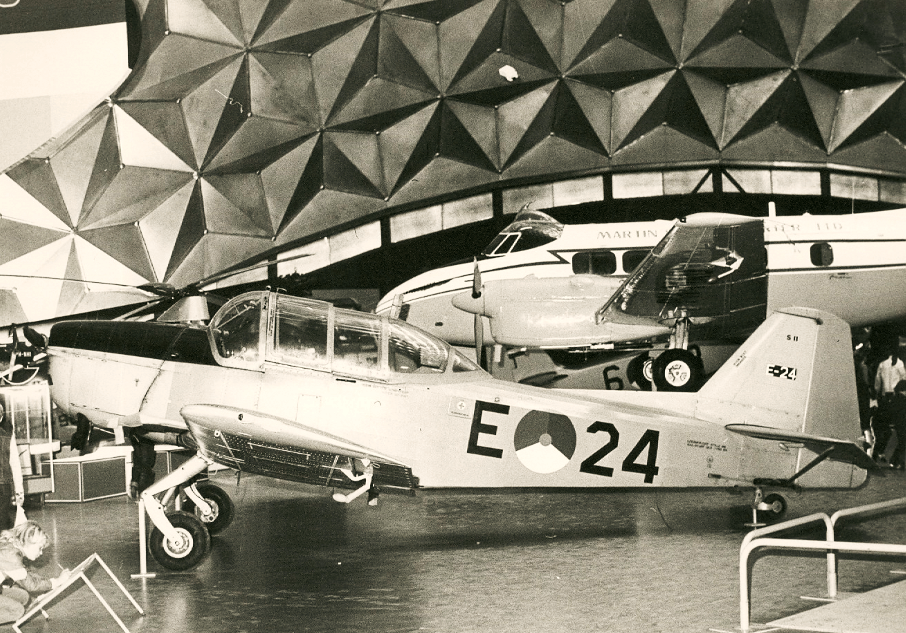

The E-24 was included in the collection of the then Aviodome, which was located at Schiphol Airport.

The S-11 was also a popular object of study for education in the aviation sector, TU Delft received an S-11 just like the Anthony Fokker school in The Hague.

Many aspiring aircraft mechanics gained their first key experience at the Anthony Fokker school, including the S-11.

In the 1970s, many S-11s also changed hands quickly from one owner to another for various reasons, perhaps even commercial ones.

The exact life history of each S-11 built is stated as best as possible in the later chapter “Overview of all built S-11s, M-416s, T-21s and T-22s”

In 1979, six years after the last phasing out of the S-11 at the MLD, eight airworthy S-11s were registered in the Dutch Aviation Register, the

PH-HOE, HOK, HOG, HOI, GRY and SLO, all privately owned.

The PH-HOE and the PH-HOG were also deregistered from the Aviation Register in the same year.

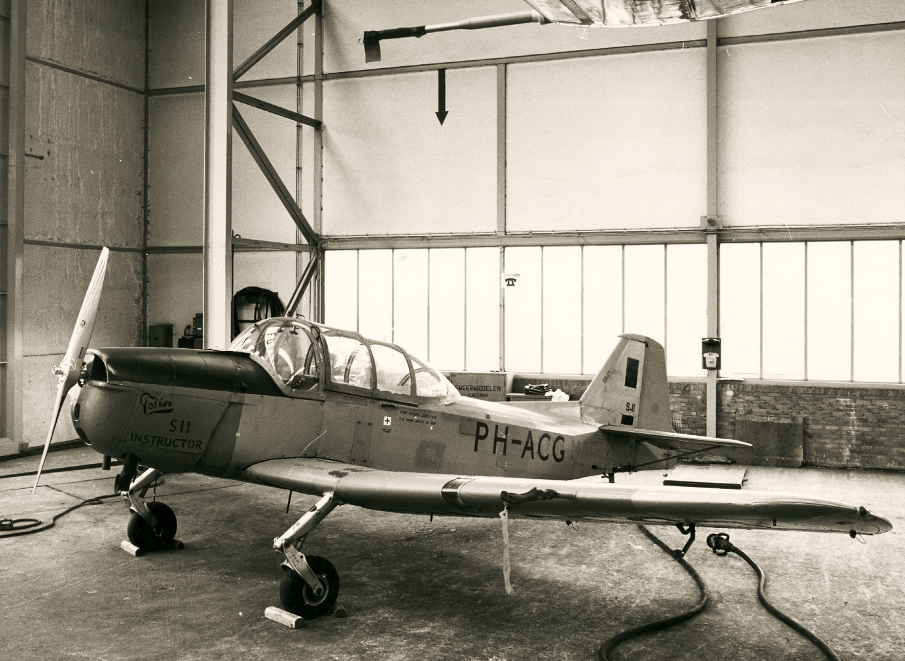

The PH-GRB flew with the Stichting Vliegsport Gilze-Rijen and the PH-ACG with the Dutch

Historical Flight.

The S-11 was not very well known to the public, occasionally one could be seen at an air show or at the (then) annual open day of the Royal Netherlands Air Forces and then usually on the ground at the so-called static show.

At the beginning of 1979, for the first time after 28 years, an S-11 was parked at the Fokker factory at Schiphol-East.

The PH-ACG, ex E-36 of the Royal Netherlands Air Forces, stood in Hall-13 of the flying company next to the then present F-27 and F-28 aircraft.

The plane was bought in 1976 by eight Transavia pilots who regularly took it to air shows at home and abroad and other aviation manifestations.

Most of the eight Transavia pilots had had their own training on the S-11 at the Royal Netherlands Air Force, the PH-ACG had 3500 flying hours in the log in 1976.

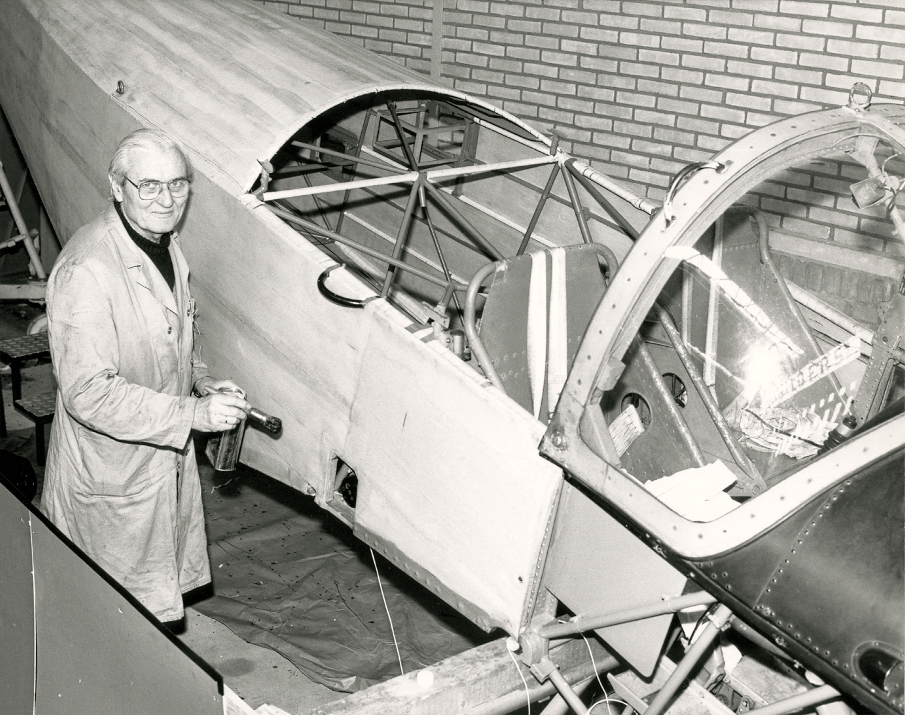

The aircraft was not only allowed to be parked at Fokker, it also received a major overhaul there by a number of Fokker retirees and volunteers.

The volunteers spend a lot of hours in their spare time on the S-11, it was also re-covered with linen by the pensioners, some of them still mastered this technique of lining.

Finally, it got a new paint scheme in the former Air Force outfit as E-36 and the aircraft could last for years.

Initially, the aircraft was taken to a VHV shed in Nes aan de Amstel for an initial inventory to determine the overall condition of the PH-HOG.

It soon became apparent that the aircraft could be brought back into airworthy condition, but that it would not be serviced as with the

PH-ACG, but a thorough restoration program.

The VHV warehouse in Nes aan de Amstel turned out not to be suitable for such a major restoration.

Fortunately, the Fokker factory provided the solution, by granting permission for the PH-HOG to be placed in Hall-13 of the flight service.

This second S-11 project at Fokker in 1979 was also carried out by Fokker pensioners and many volunteers.

The restoration also took place in a hangar approved by the RLD with the right resources, tools and materials.

The project was led by Fokker employees Piet Wey and Jan Gans, they had the right knowledge because they had worked on the production of the S-11 in the early 1950s.

Both Fokker employees had control authority at Fokker, so that they could check all work performed and stamp the relevant papers.

The aircraft was painted in its old MLD livery as 199 with a small VHV logo on both sides of the fuselage.

On August 26, 1981, the PH-HOG made its first flight at Schiphol after the thorough restoration, after which it received the new certificate of airworthiness from the RLD.

All kinds of activities were organized on the large market in Haarlem because of the fact to commemorate.

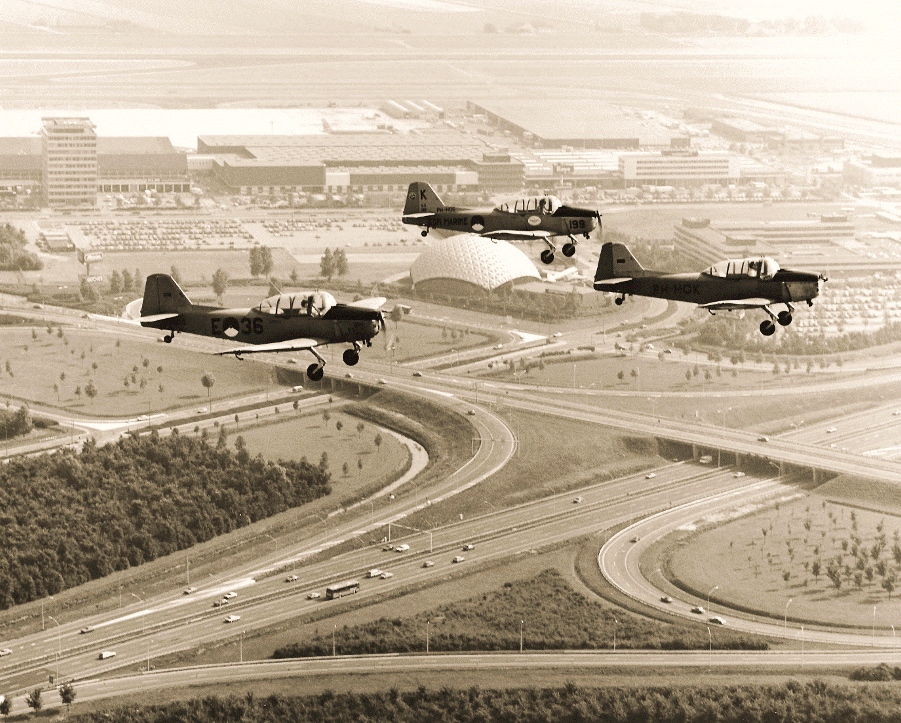

In the afternoon a formation of three S-11s flew an F-28 over the Grote Markt in Haarlem, quite unique because such a formation had not flown in years.

The S-11 formation consisted of the newly restored PH-ACG and PH-HOG, plus the PH-HOK.

From 1979 to the mid-1980s, several S-11s at Fokker have had the opportunity to be fully restored, or to undergo maintenance, carried out by Fokker retirees and volunteers.

S-11s owned by owners who made their S-11s available to the Fokker Four team were given a new color scheme in Fokker's aircraft paint shop, sometimes with the old Air Force or MLD registrations.

For example, to the delight of many S-11 owners, the Fokker factory acted as a sponsor for its own product from the 1950s after the phasing out at the KLu/MLD.

Fokker Four

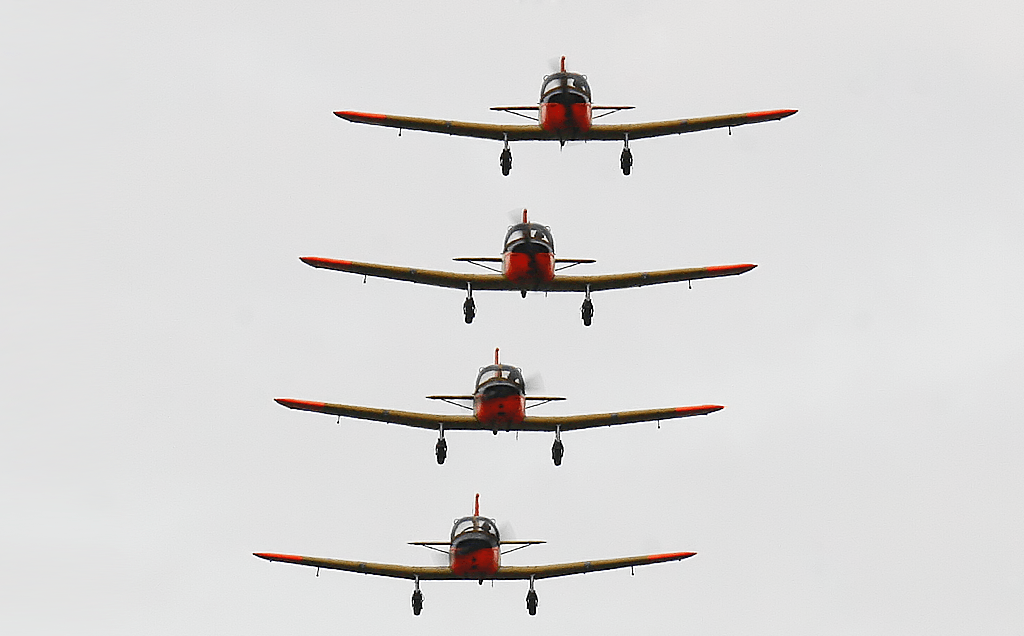

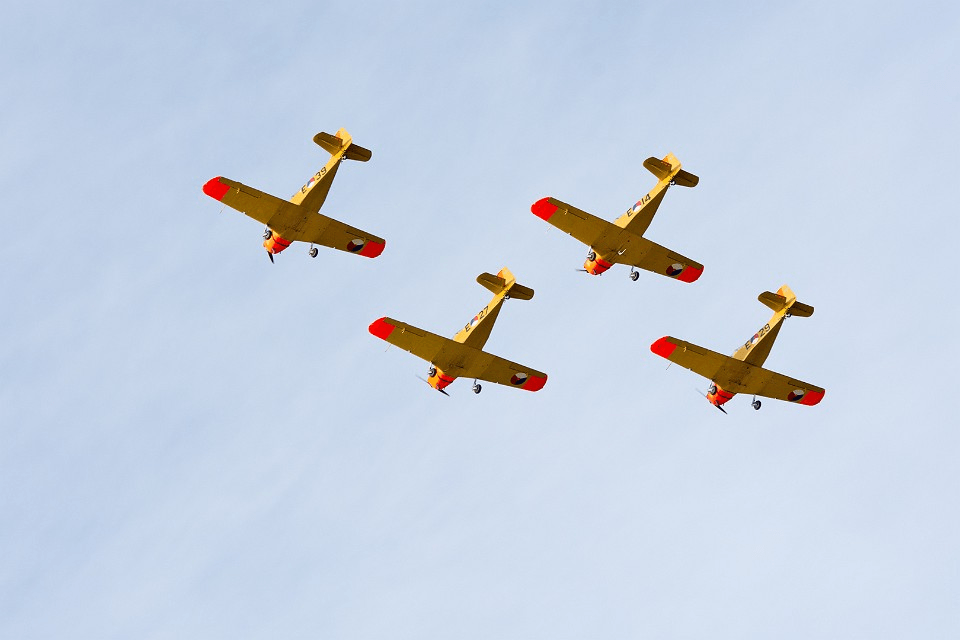

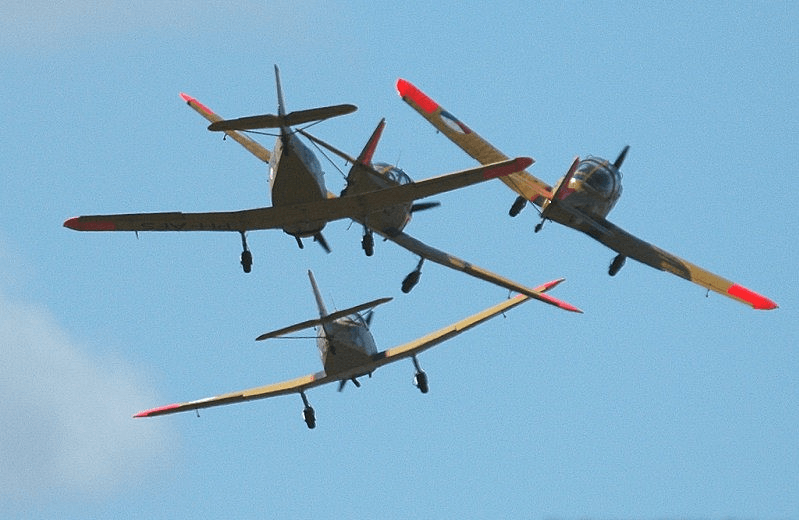

The formation of the three S-11s that had given a demonstration over the Grote Markt in Haarlem on September 4, 1981, prompted a number of S-11 owners and Fokker employees to form a demonstration team with 4 S-11s.

After all, the S-11 is suitable for aerobatics or Aerobatics, Fokker wanted to act as a sponsor and so the idea came forward to establish the "Fokker Four".

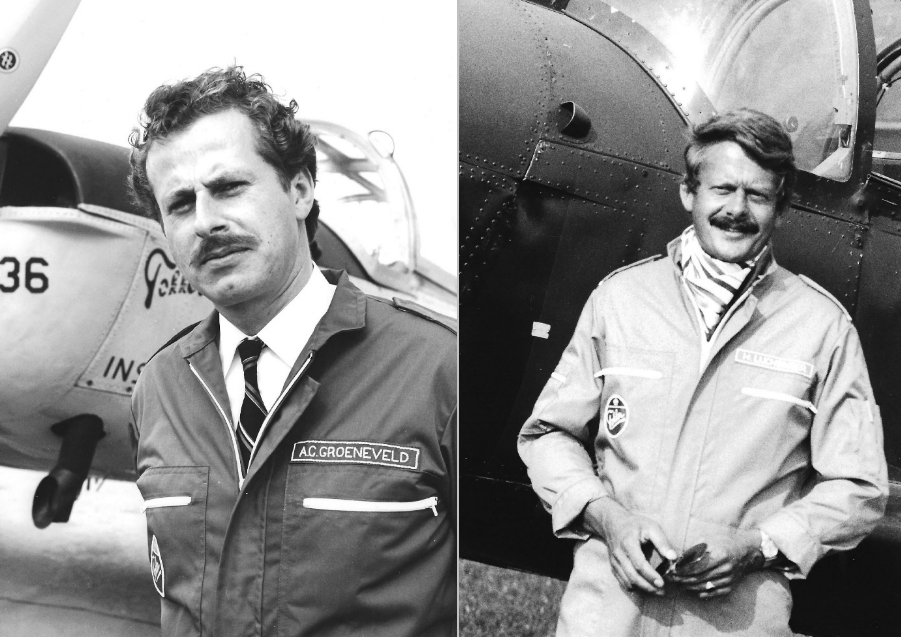

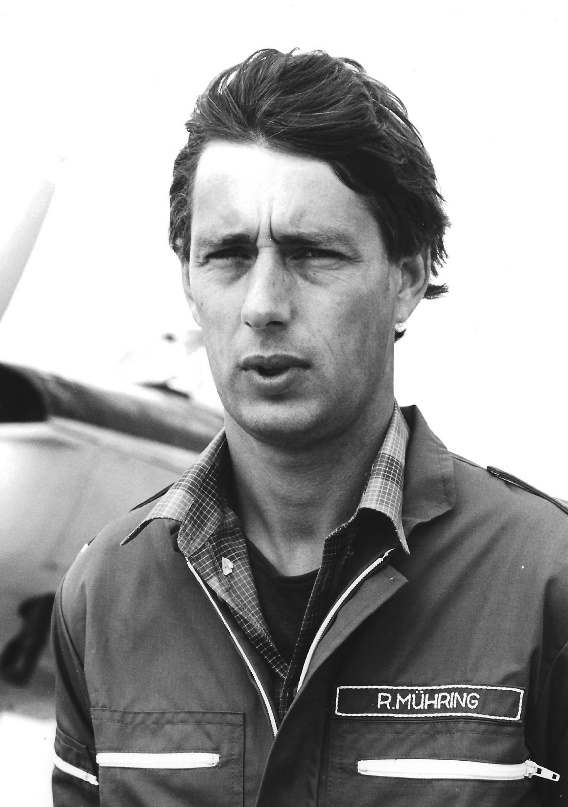

After the necessary technical and administrative preparations and the constant availability of 4 S-11s, the Fokker Four was presented to the (aviation) press on August 30, 1982.

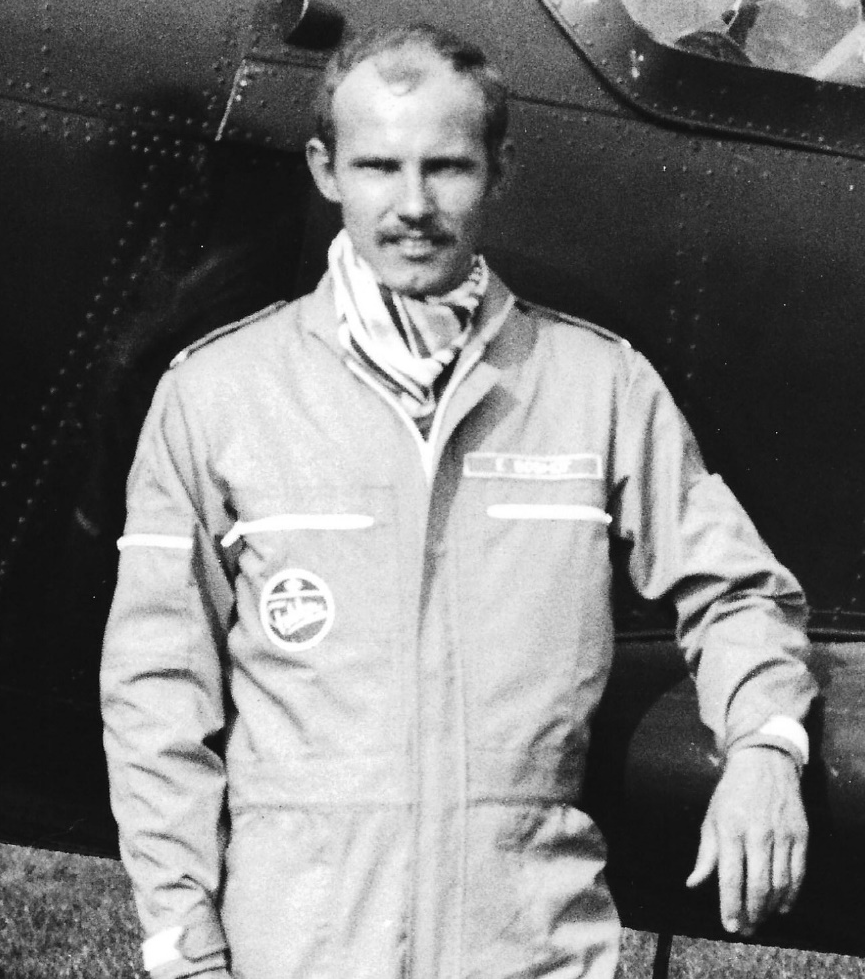

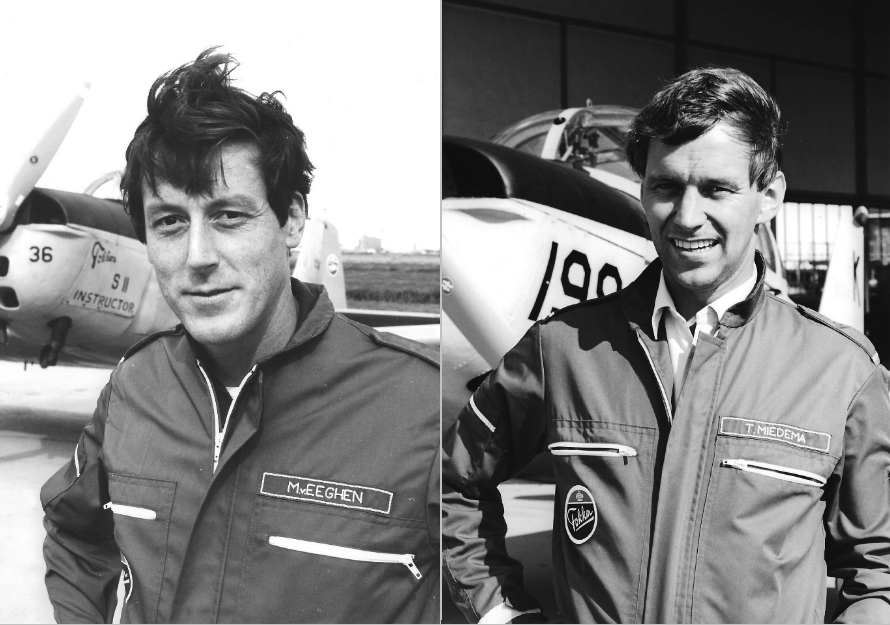

A press kit was issued with the necessary information, the S-11 pilots were extensively presented with their photo with relevant information.

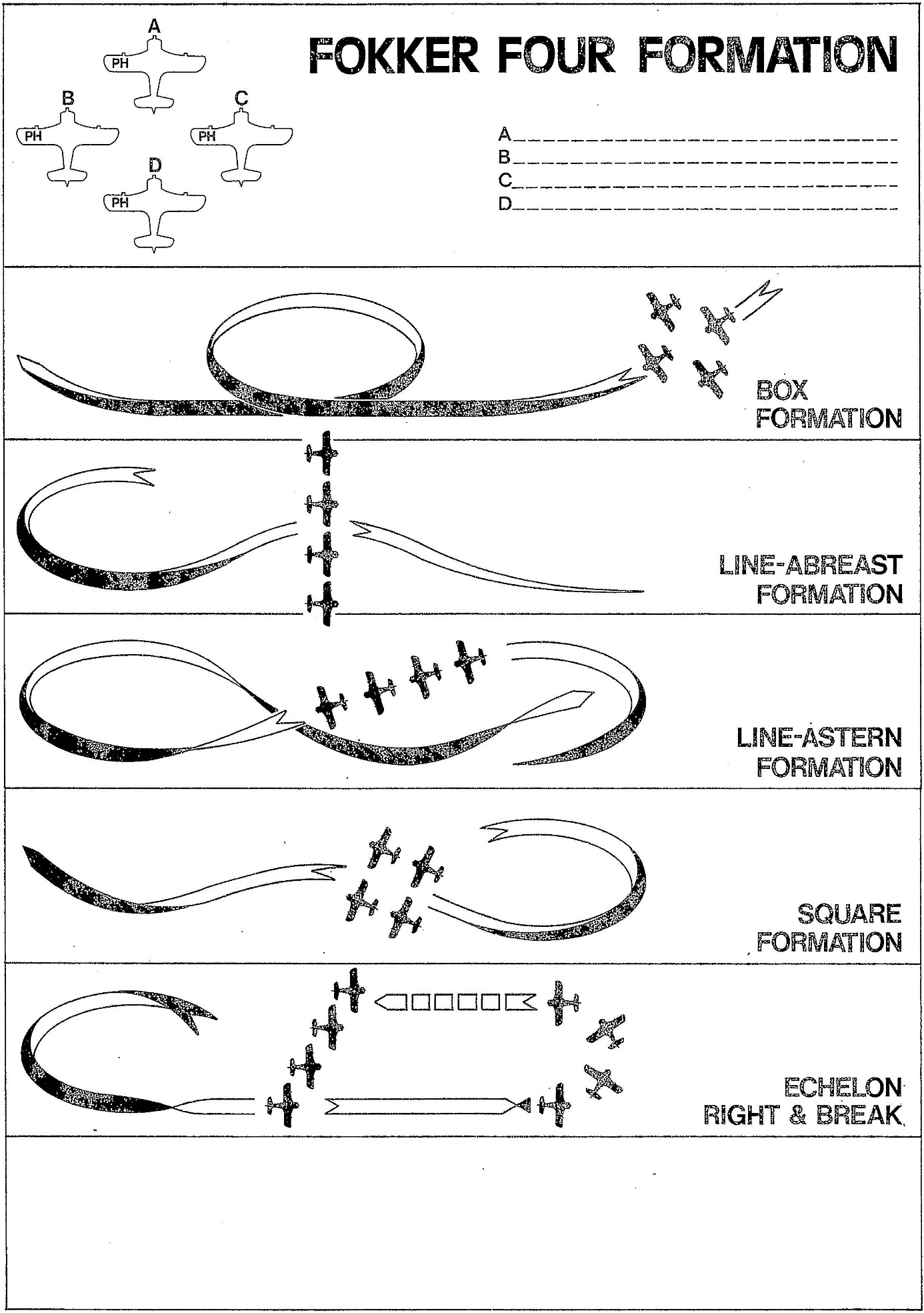

An image was also attached with examples of the aerobatics to be flown that the Fokker Four would give at air shows and other aviation manifestations.

Later a number of Aerobatic figures were added.

The first board of the “Fokker Four Foundation” when it was founded in 1982, was composed as follows:

Chairman, Gerard Schavemaker.

Vice-chairman, Anne Cor Groeneveld.

Secretary/promotion, Ria van Oeveren.

Treasurer, Jan de Groot.

Flight affairs, Cor de Blij.

Technical service, Jan Gans.

Here is the official announcement from the Fokker Four's press kit.

Above Hal-B at Fokker, a warehouse was built for the storage of parts and tools.

The space could also be used as a workshop for the repair or maintenance of parts and, not unimportantly, there was room for the creation of a small bar.

There was also room for board meetings, etc.

Over the years there have also been changes within the Fokker Four, the board has changed several times and in the mid-1980s there was no hangar space available at Fokker anymore due to the Fokker 50 and Fokker 100 production.

The S-11s of the Fokker Four then moved to the hangar of the Dutch Dakota Association at Schiphol-East and finally to a hangar at Lelystad Airport.

The composition of the technical service and the pilot corps has also been changed several times.

Existing sponsors dropped out and others took their place.

The S-11s themselves also changed, when an aircraft was under maintenance, the owner of an S-11 was called upon to participate in the Fokker Four formation.

Some owners of an S-11 continued to own the aircraft, while the aircraft participated in the Fokker Four Foundation.

At the moment the Fokker Four team consists of the PH-AFS, PH-HOK, PH-HOG and PH-HOL, all owned by the Fokker Four Foundation, as back-up use can be made of the PH-SLO and the PH -ACG.

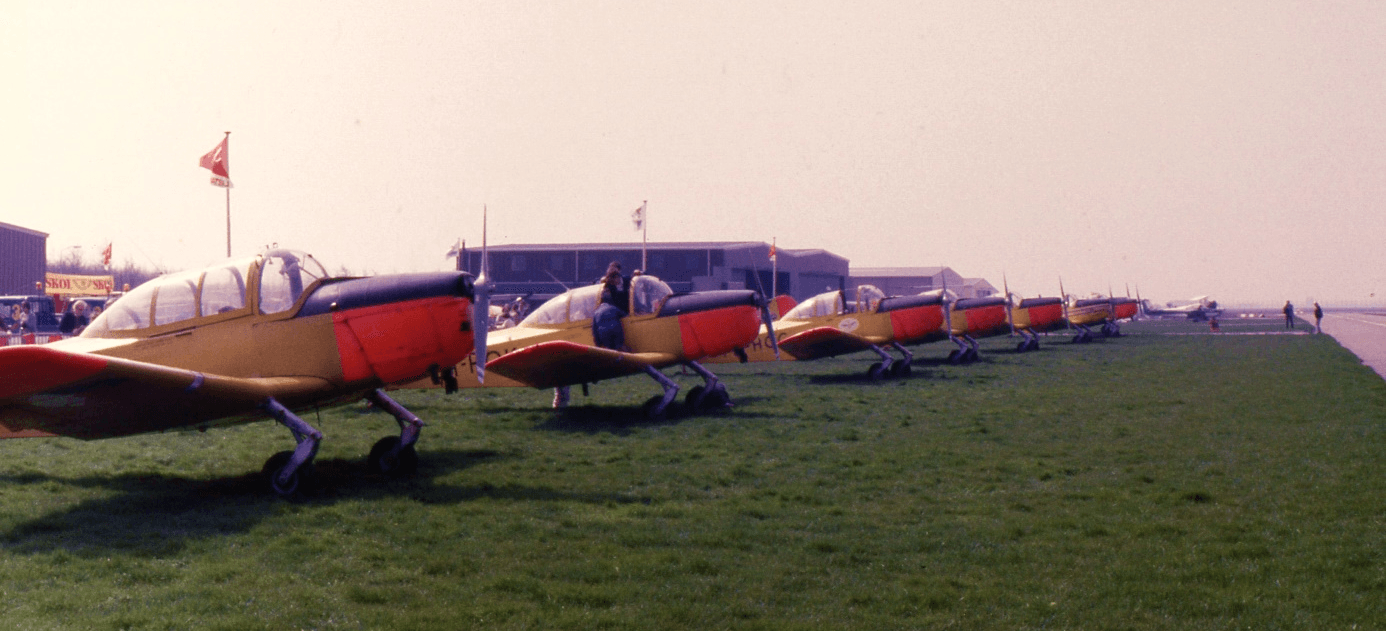

On April 16 and 17, 1983, the Fokker Four organized the 1st Fokker Four Fly-In at Lelystad Airport, with the aim, among other things, to get as many S-11s as possible to Lelystad.

No fewer than eight S-11s were present at the air show, five from the Netherlands, two from Belgium and one from England.

Of course the Fokker Four presented a great air show.

In November 1983 the Fokker Four was used for a promotional tour for Schiphol Airport.

In the years that followed, the Fokker Four still regularly organized Fly-Ins and took part in numerous aviation events.

It was then 75 years ago that Anthony Fokker did that with his Spin..

On November 15, 2016, the "Bicycle of Messel Award" was presented to them in the Aviodrome Aviation Theme Park in Lelystad for their unbridled efforts to bring the fleet of the Fokker Four Foundation into top condition and to get them airborne in a safe and responsible manner. to hold.

Every two years, the National Federation for Historic Aviation presents the Fiets van Messel Award to someone or an organization that has made a valuable contribution to historic aviation in the Netherlands.

The award is named after former KLM pilot, Gerson 'Fiets' van Messel, a pioneer in Dutch aviation history and advocate of historic aviation.

The technical team was awarded the award by the judges, Ben Droste, Peter Legro, Martin Schröder and Leo Visser.

All technicians work as volunteers.

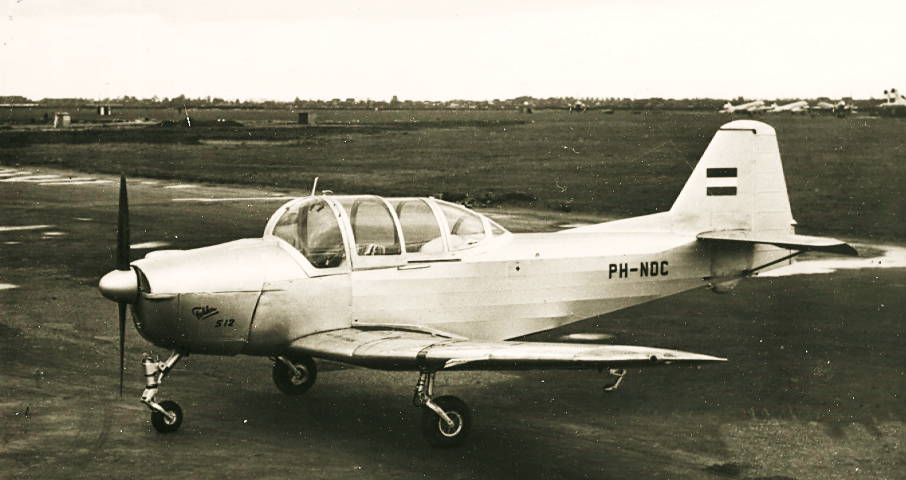

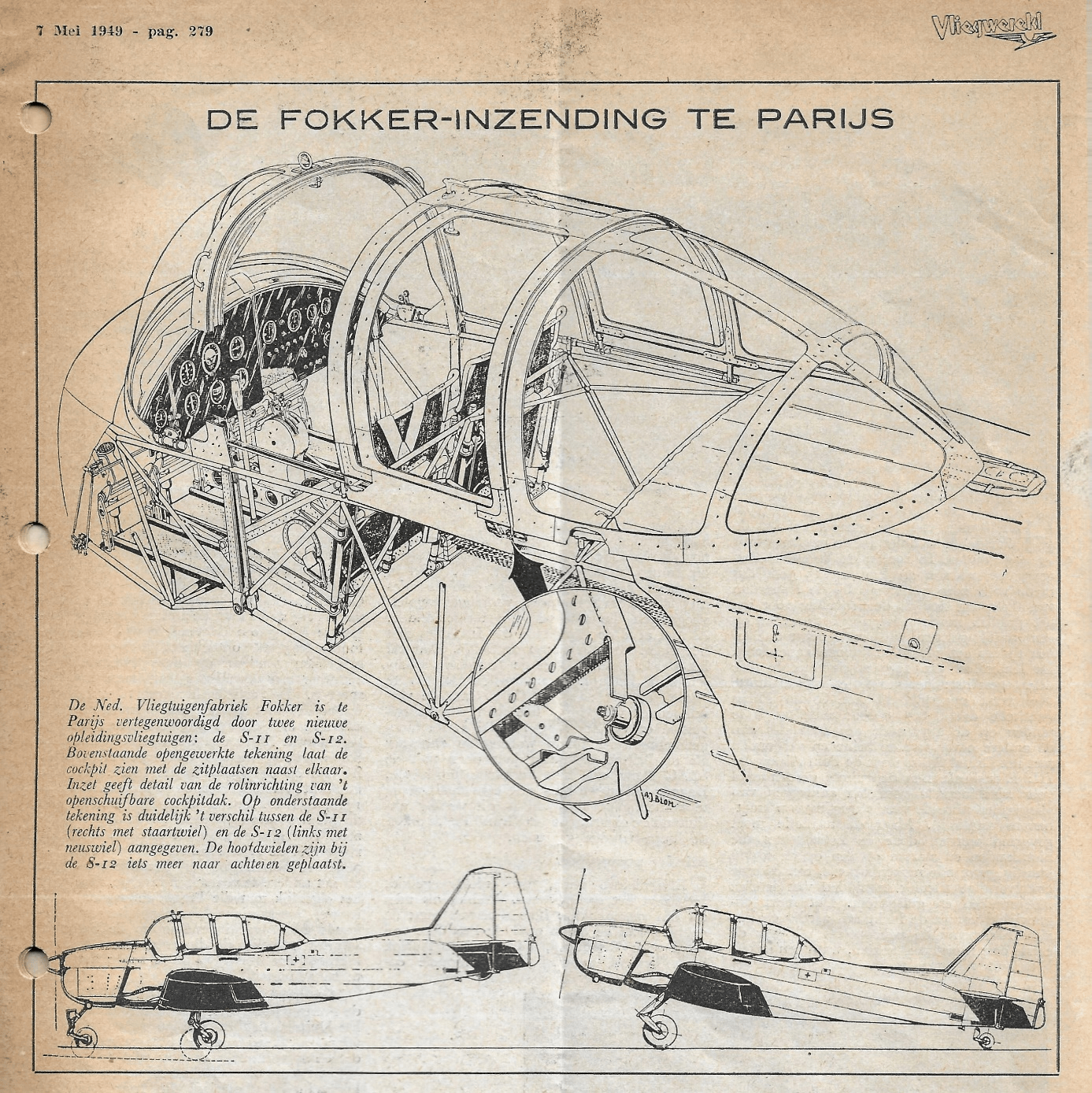

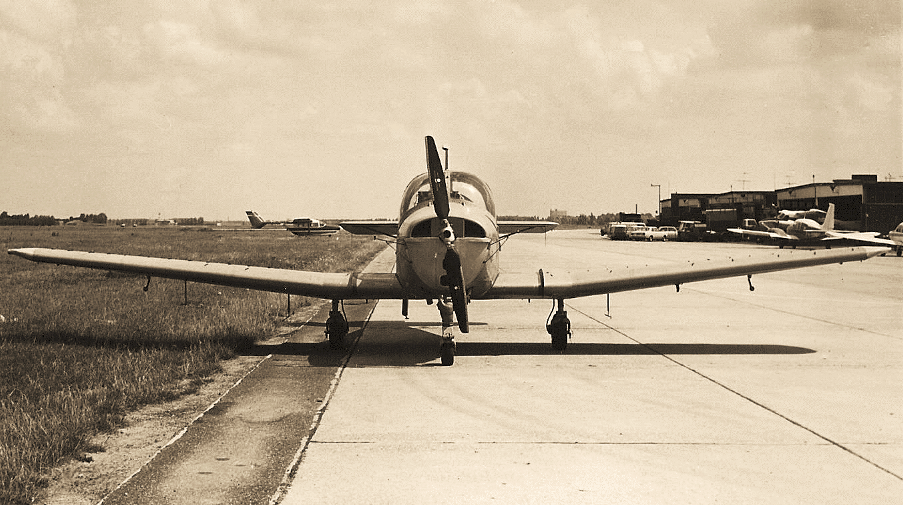

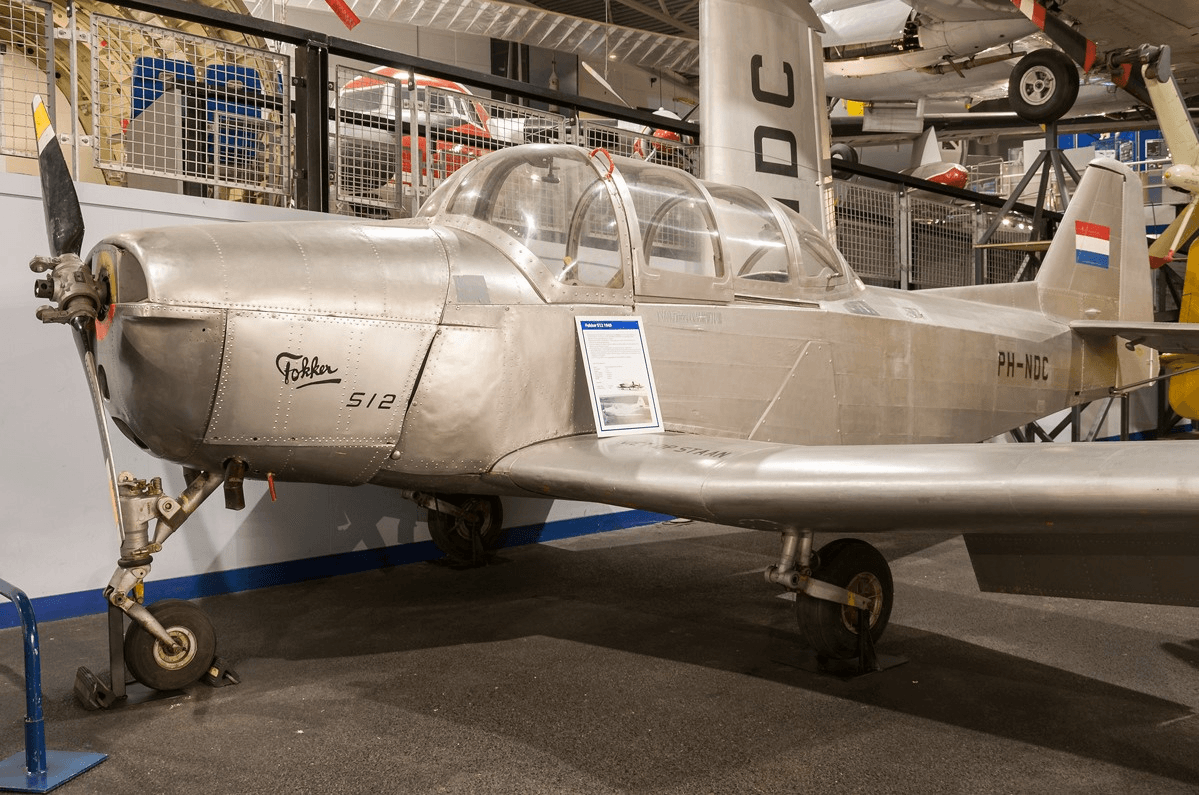

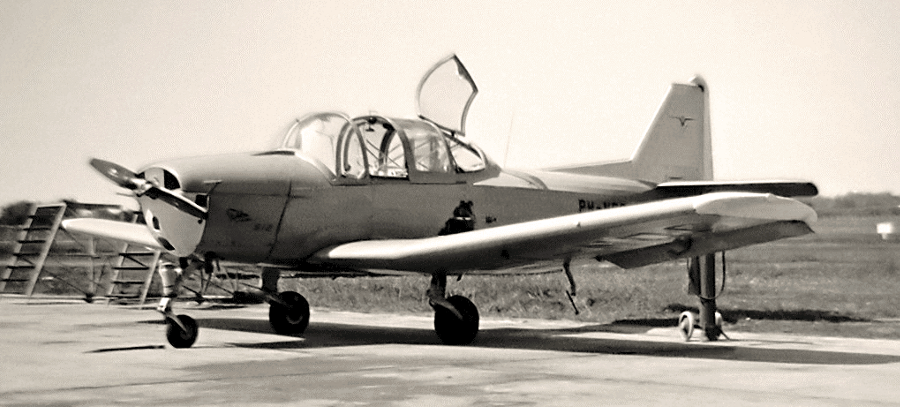

The idea of a nosewheel version of the S-11 arose at the same time as the development of the S-11.

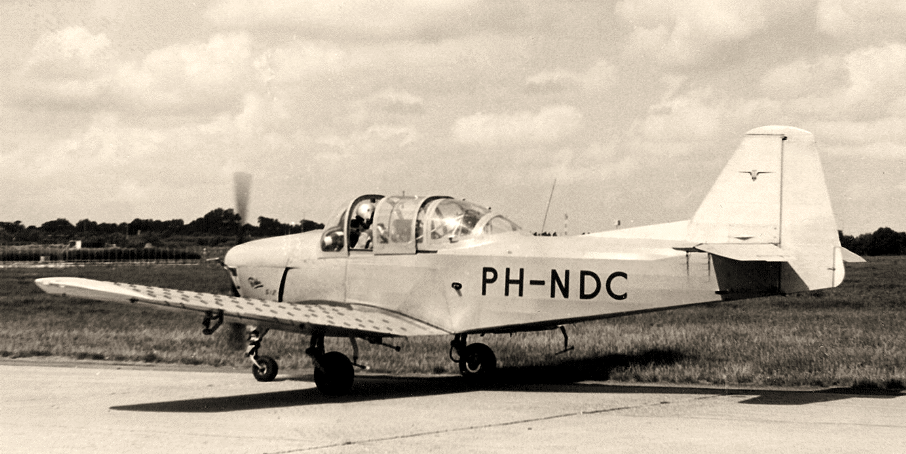

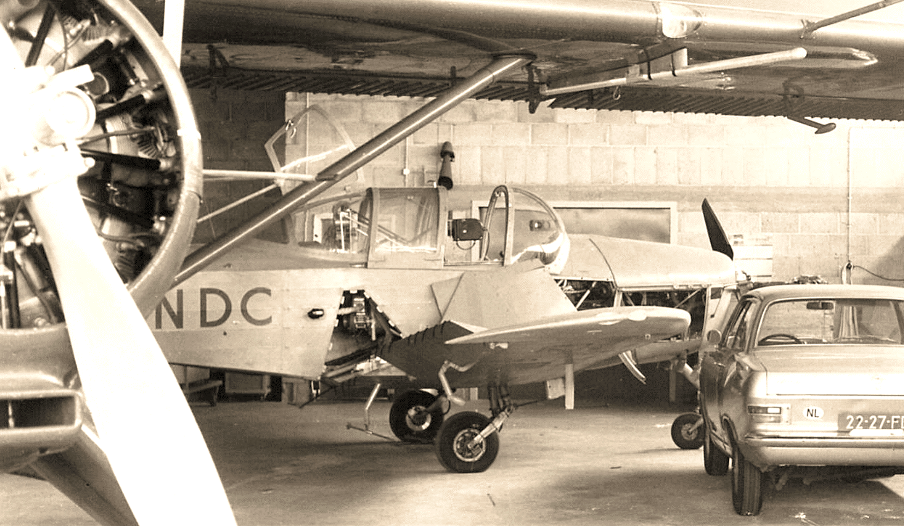

This was also apparent from the production of the S-11, where the third production S-11 was converted into an S-12, it received cn 6287 and was registered in the aviation register on November 15, 1948 as PH-NDC.

A choice could thus be made to train pilots who would later fly tailwheel aircraft, or on aircraft with a nosewheel, such as the DC-4 back then.

The advantage of the S-12 was that during taxiing there was an even better view for the pilot on the runway.

Because the center of gravity of the S-12 was in front of the main landing gear, the aircraft was less sensitive to crosswinds during taxiing, and it was also possible to brake more powerfully on the ground.

A disadvantage was that the S-12 had a slightly heavier construction.

The first flight took place on November 8, 1948, just like the S-11 by the pilot of Fokker, Gerben Sonderman.

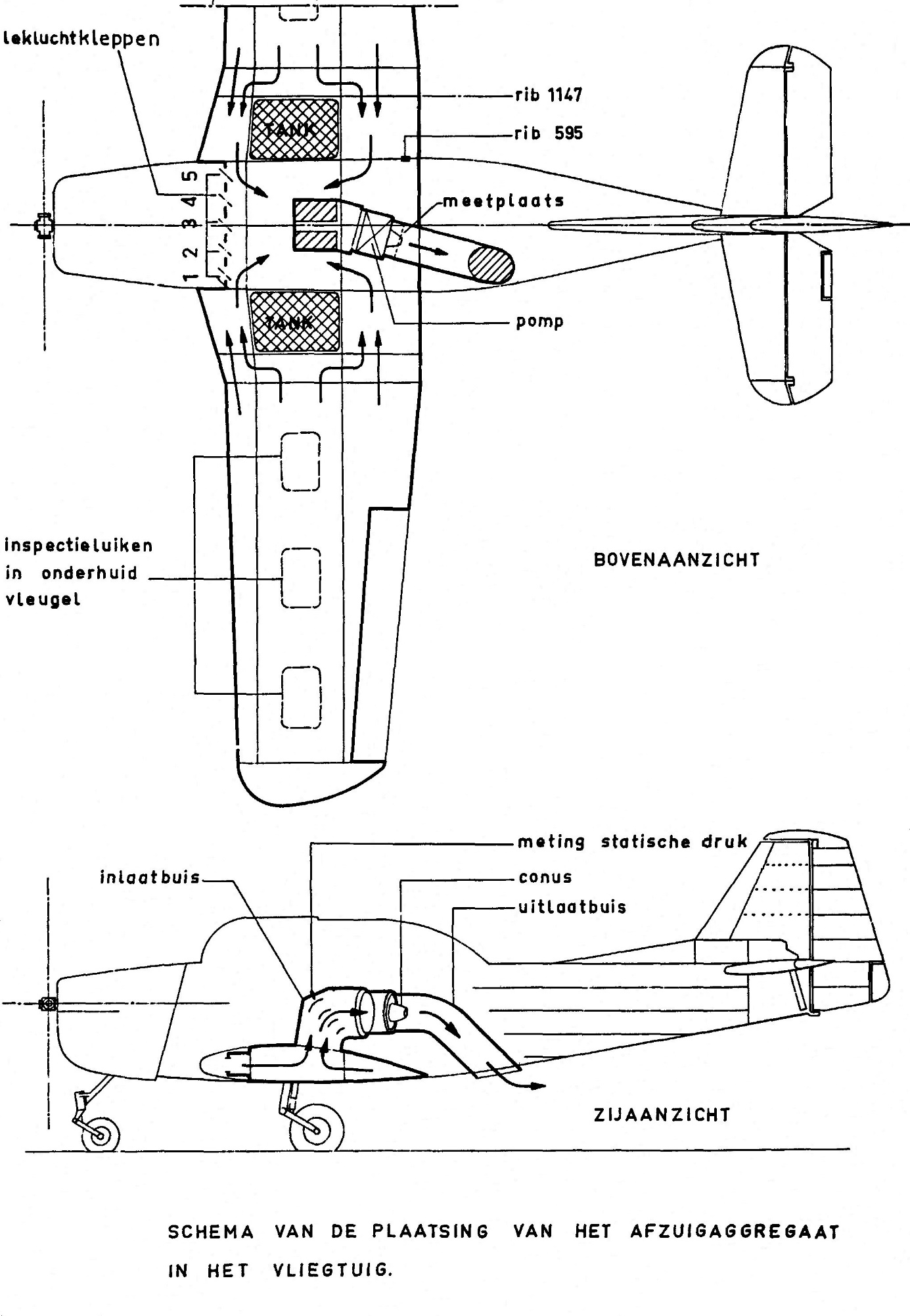

The S-12 may not have been a commercial success, but at the NIV in the late 1950s and early 1960s it still served as an experimental aircraft for a number of important tests in the field of boundary layer extraction.

The boundary layer on an aircraft is the invisible airflow that passes over the top of the wing during flight, giving the aircraft lift and allowing it to fly.

The lift is optimal when the airflow runs over the entire airfoil from the front to the rear.

If the angle of attack of the aircraft is too great, the airflow at the rear of the wing will loosen and there will be less lifting power.

The angle of attack is the position of the aircraft relative to the horizon, so if the nose of the aircraft goes up and the tail goes down, there is reduced lift.

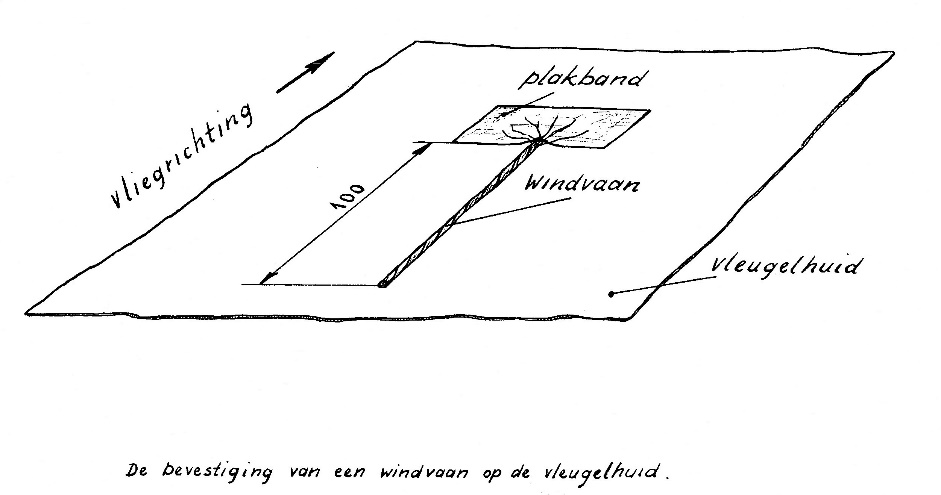

The airflow over an airfoil can be visualized with smoke in a wind tunnel or with woolen threads on the wing during a flight.

In 1959 the S-12 had a major overhaul in the

Fokker's development department.

On 1 July 1959 the S-12 was handed over to the NIV, two days later the NIV handed over the S-12 to De TH Delft, who carried out all the tests.

The trials with the S-12 were conducted from Zestienhoven airfield, where the TH had a hangar where the S-12 was prepared for numerous experimental flights.

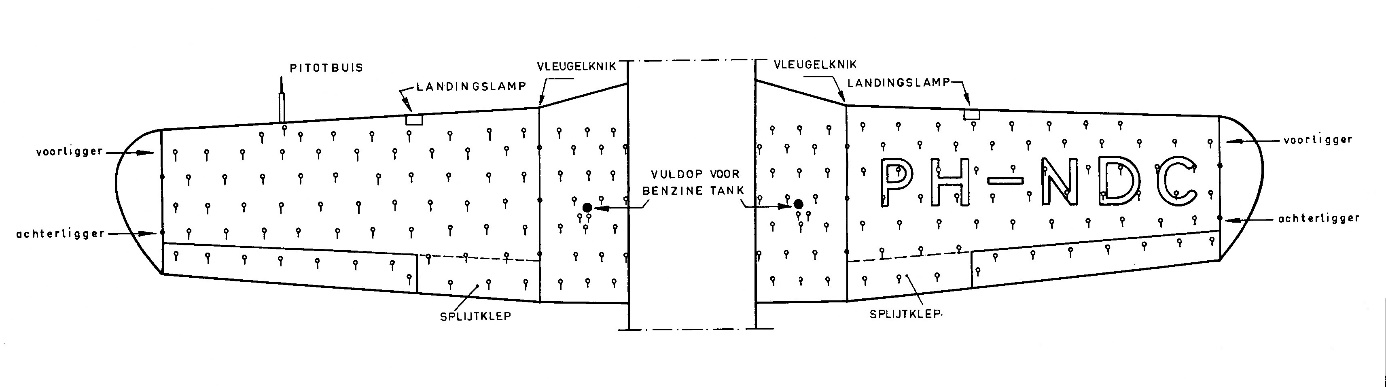

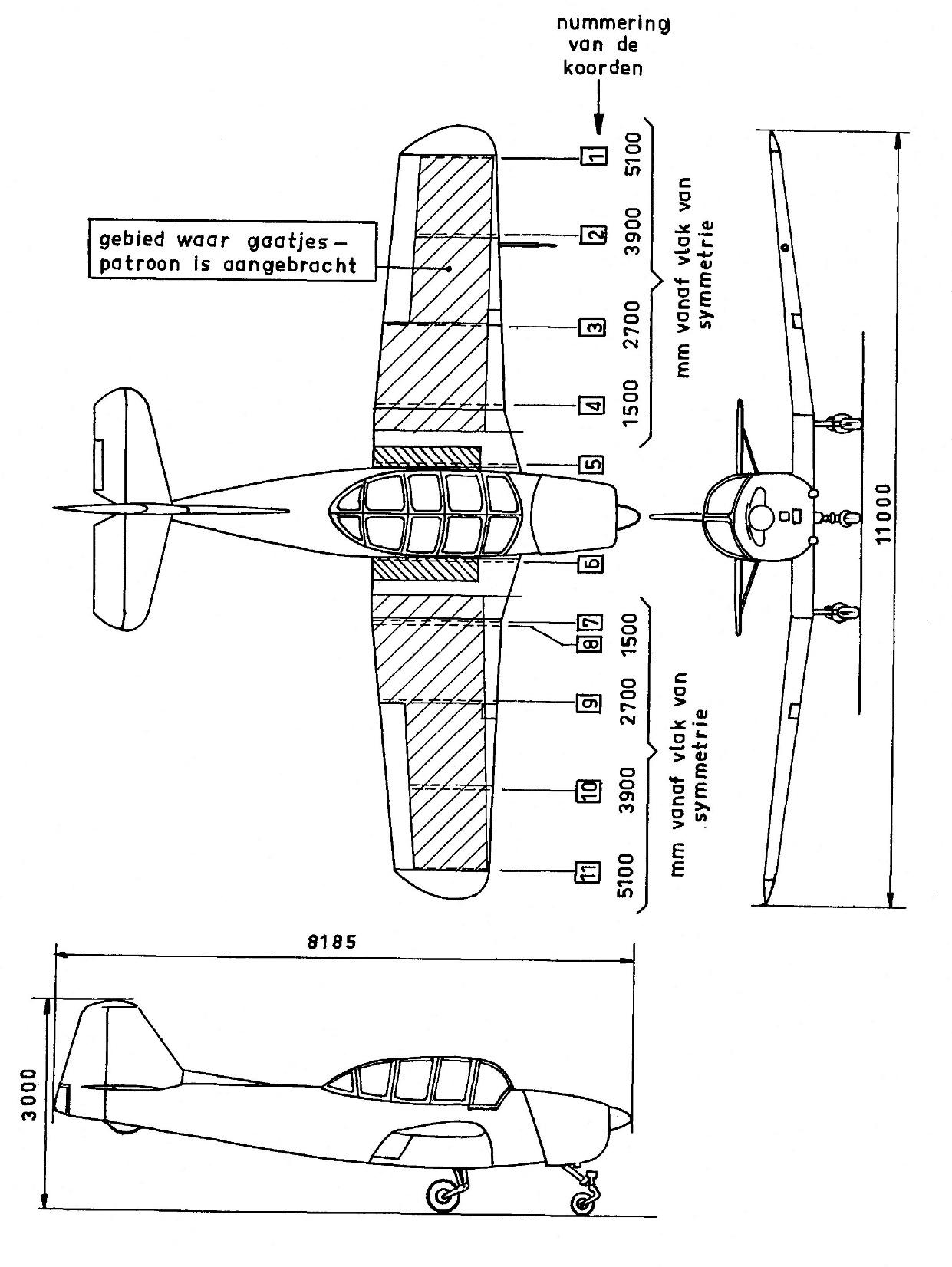

To visualize the airflow over the wing, the S-12 was fitted with nearly 200 woolen threads, 10 cm long, on the top of the wing.

During the flight, an observer was on board who had access to a Contax small image camera with a 90° wide-angle lens and a 16 mm Paillard film camera with a 70° wide-angle lens to monitor the behavior of the wires and thus the airflow during the flight. , was able to photograph and film.

At high speed in a straight flight, the threads stuck to the wing surface and at low speeds and a higher angle of attack, the threads and thus the airflow at the rear of the wing released.

In this way the airflow, or boundary layer, could be observed in all flight situations. In these tests the S-12 was equipped with the standard wooden propeller.

All data from the test flights where the boundary layer was observed at different speeds, angles of attack and flight altitudes were recorded in a report.

This data was used in a subsequent experiment with the S-12, boundary layer aspiration.

For the tests with the boundary layer extraction, the S-12 was thoroughly rebuilt, in 1954 the aircraft was registered in the aviation register as S-12-X and it had become an Experimental aircraft.

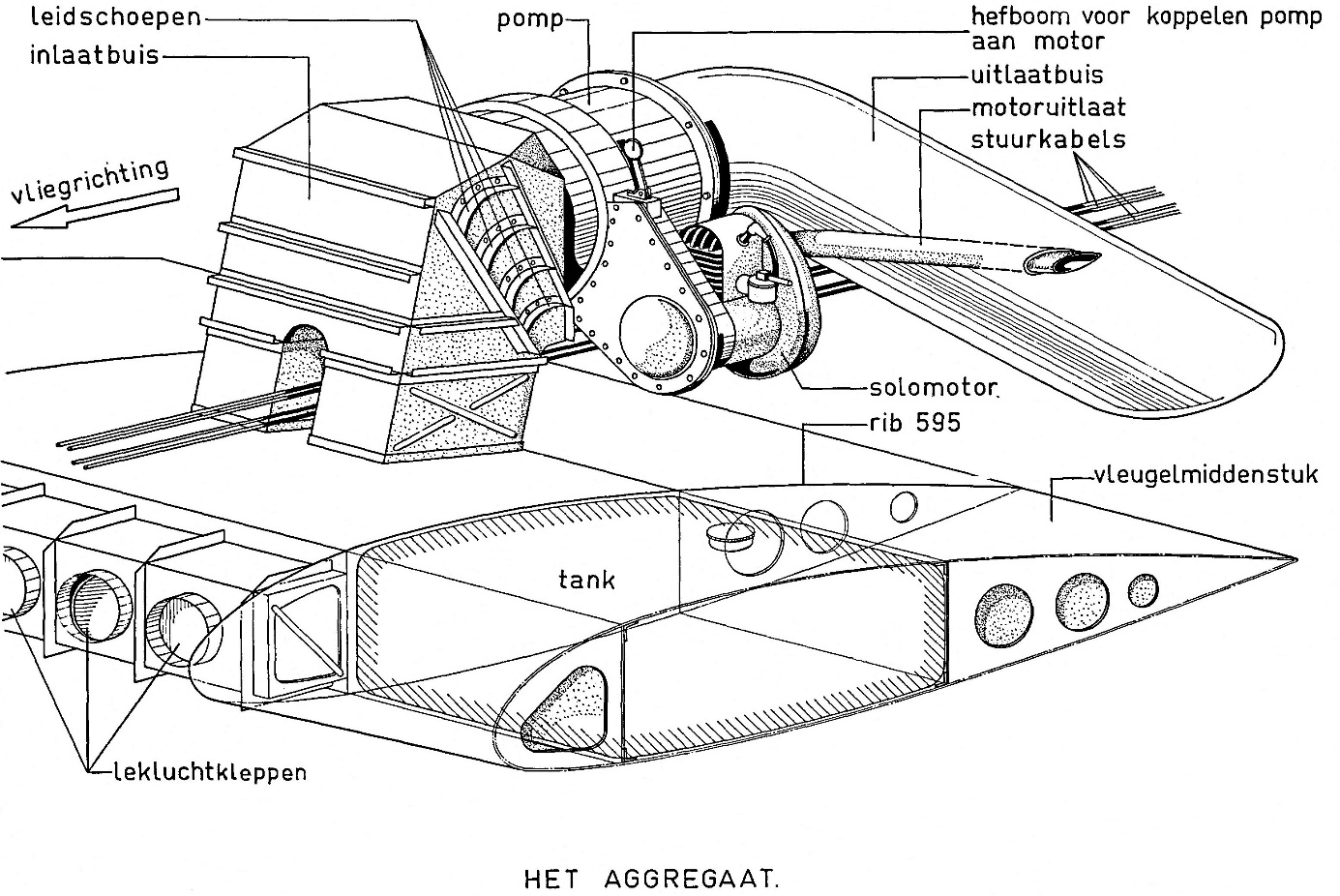

The renovation in 1953 consisted of a newly built wing at Fokker, which was for the most part glued.

From the kink on the left and right where the V-position started, the outer wings could now also be disassembled.

The bolted connection of the wings was accessed by removing the panels on the underside of the wing.

These access panels were also installed in the S-11 wing for maintenance or repairs in the wing.

An Aeromatic propeller was mounted on the hub and the maximum take-off weight of the S-12 could be increased from 1100 to 1200 Kg.

The pump that was to ensure the extraction of the boundary layer through the holes in the wing was placed in the fuselage.

This axial suction pump was driven by a V-belt from two Solo, one cylinder two-stroke petrol engines of 125cc with a power of 5HP each.

Boundary layer baffles ensure that the boundary layer is directed towards the rear of the wing and does not deflect towards the wing tip, decreasing lift.

A boundary layer bulkhead looks like a narrow upright strip across the wing leading edge.

The tests were carried out both on the ground and during flights, on the ground the suction pump was driven by an electric motor.

The shape of the wing tips was also changed and the landing lamps in the modified wing leading edge were removed.

All the results of the experiments were later certainly used in the aircraft engineering course at the TH in Delft.

Construction no. Registration. Employed. Comments.

6287 PH-NDC 15-11-48 Fokker.

PH-NDC First flight 08-11-48

PH-NDC 22-03-54 Type changed to S-12-X due to

experiments NIV.

PH-NDC 11-07-56 NIV.

PH-NDC 14-01-61 TH Delft, Aeronautical Engineering.

PH-NDC Withdrawn 22-07-76, to Aviodome.